Focused on Machining has built a reputation as a top aerospace machine shop. We love the work we do for aerospace and space customers. But we want anyone reading this to know that our expertise extends into another major focus area: medical CNC machining.

Medical CNC Machining at Focused on Machining

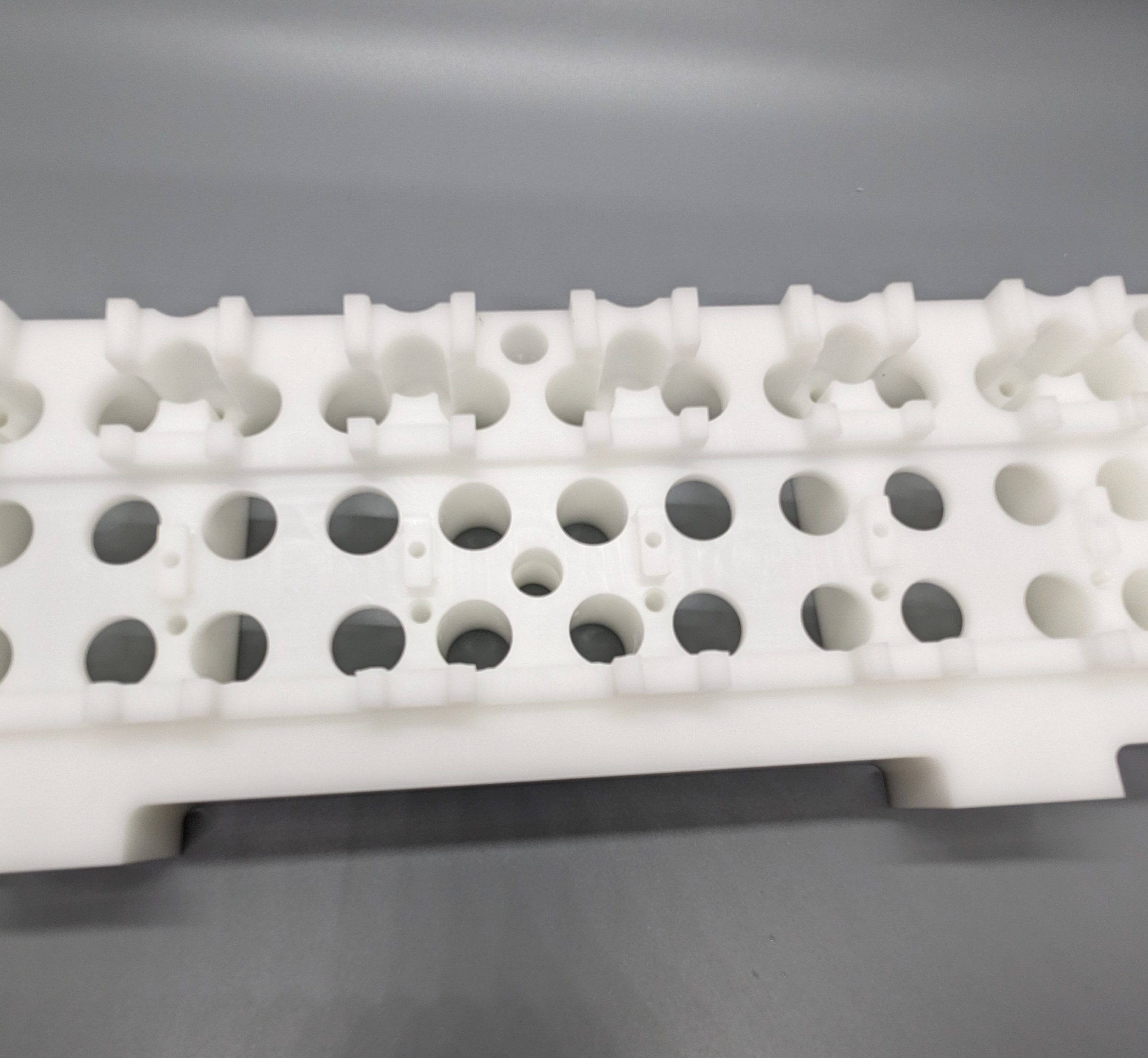

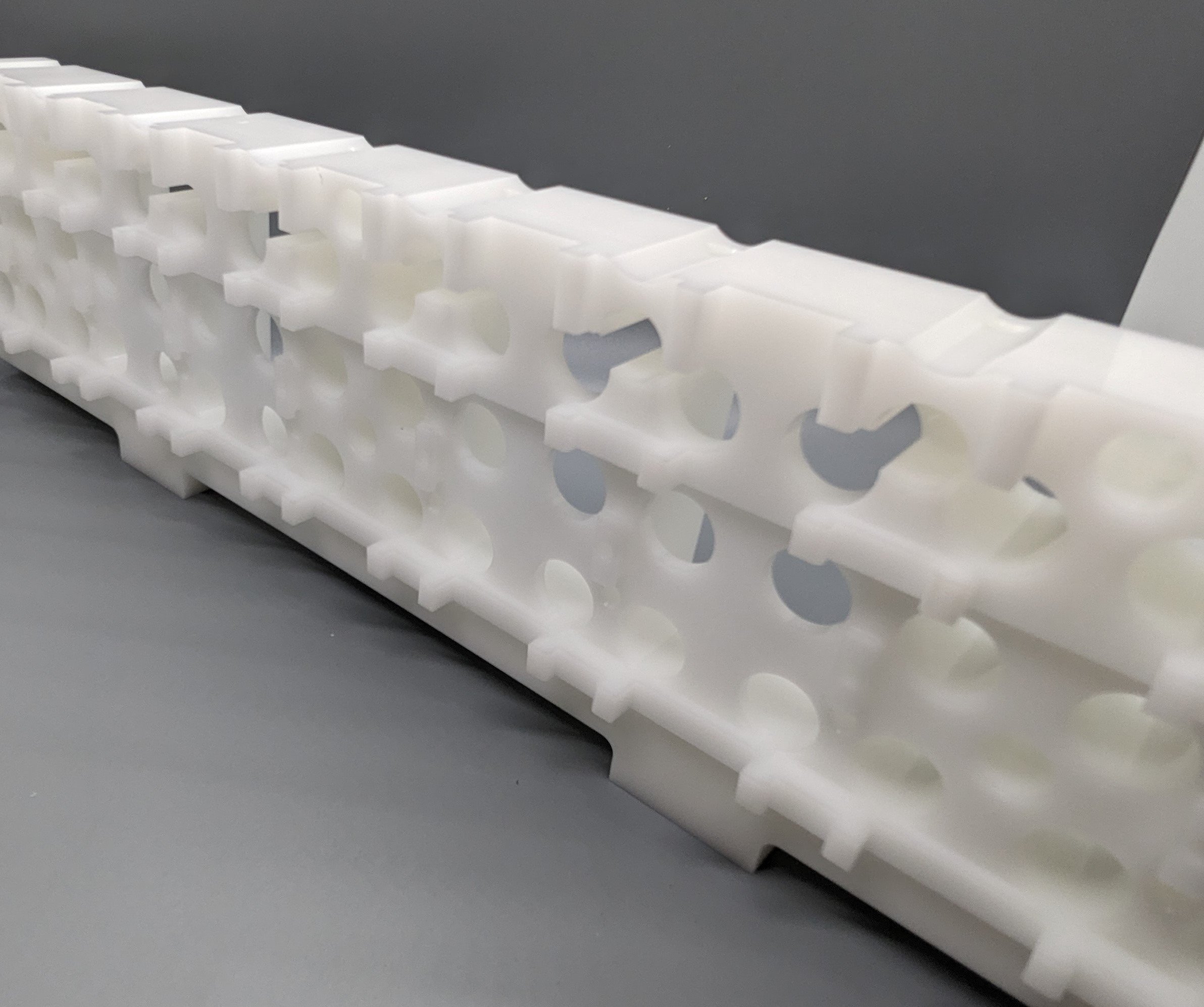

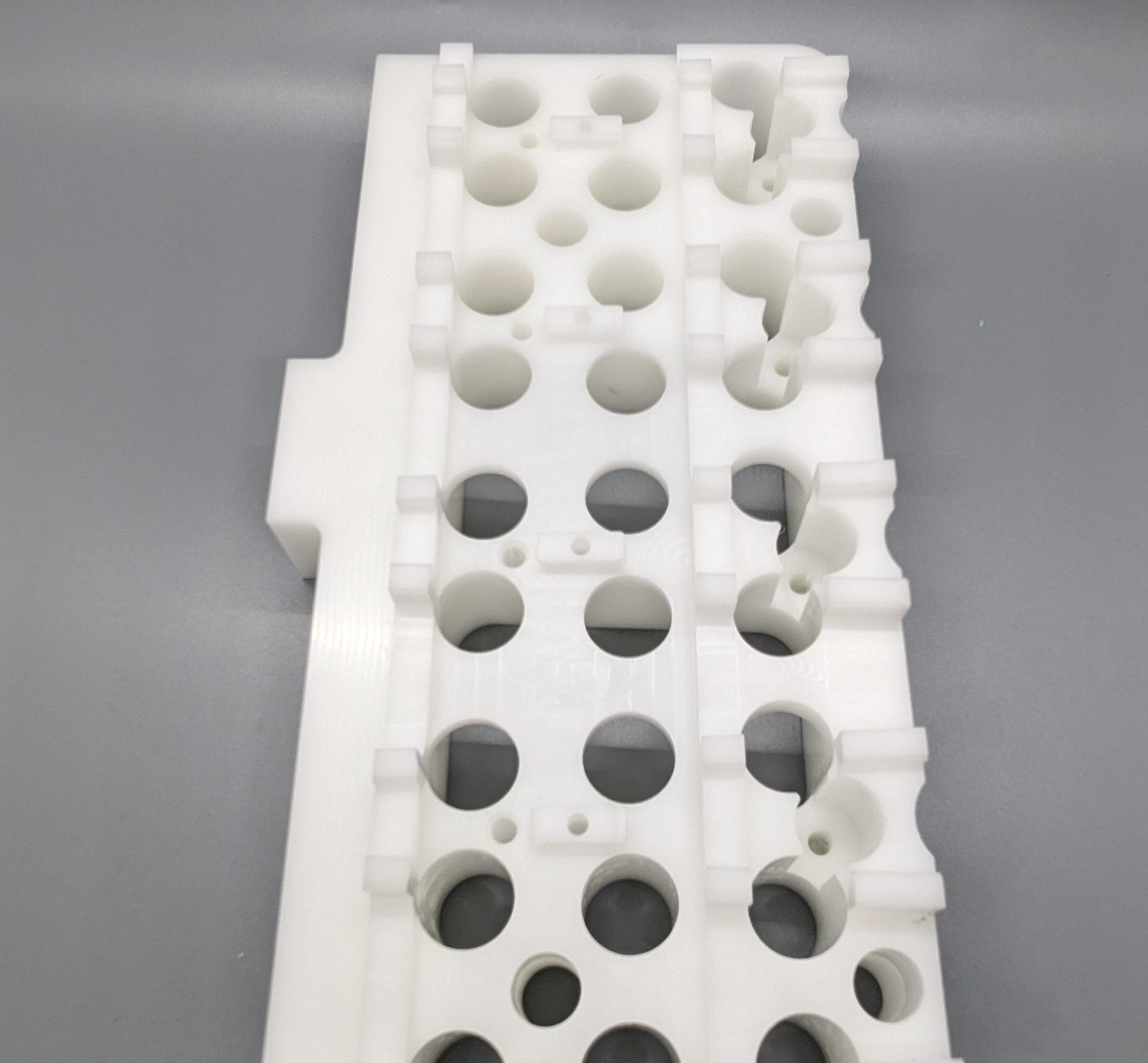

While we don’t make parts that go inside the human body, we support the medical industry by machining parts for other critical applications, like testing equipment for artificial heart valves.

The capabilities and AS9100-compliant processes we’ve developed to serve aerospace customers directly benefit medical customers in key ways:

We guarantee material traceability throughout the manufacturing process

We specialize in machining tight tolerances and intricate features

We adhere to a rigorous inspection process for every part we machine

We regularly machine materials commonly used in medical applications

Common Medical CNC Machining Materials

Let’s closely examine three of the materials we encounter most frequently for medical CNC machining projects.

316 Stainless Steel

Sometimes called 316 surgical steel for its common use in medical applications, 316 stainless steel has excellent anti-corrosive properties due to its high nickel content. It’s ideal for medical parts that come into contact with liquid in their application or must be sterilized regularly. We can coordinate passivation services with a trusted vendor to further enhance corrosion resistance.

We also regularly send 316 stainless steel medical parts out for electropolishing services per customer request. Electropolishing smooths the part’s surface, reducing microscopic cracks and crevices to achieve close to a mirror-like finish. Smooth surfaces are critical for many medical applications because the smoother the surface, the fewer opportunities for bacteria to accumulate.

Aluminum

Budget-friendly aluminum can be a great alternative to 316 surgical steel for certain medical applications. It boasts excellent corrosion-resistant properties, enabling it to withstand frequent sterilization.

A significant benefit of aluminum is that it’s durable but notably lightweight compared to other metals and alloys. For this reason, it’s commonly found in products like trays and containers, hospital room equipment, and portable field equipment.

Acetal

This semi-crystalline thermoplastic rivals metals with its excellent strength, performance, and workability. As a slippery, low-friction material, it’s a great choice for parts with sliding mechanisms.

Acetal is relatively easy to machine, enabling medical machine shops to achieve tight tolerances and complex features accurately and efficiently. It’s also possible to achieve exceptionally smooth surface finishes with acetal.

The material has good chemical resistance properties and can be sterilized using various methods.

Make Focused on Machining Your Trusted Medical Machine Shop

If you’re looking for a reliable partner for medical CNC machining services, we hope you’ll consider Focused on Machining.

We have extensive experience machining 316 stainless steel, aluminum, acetal, and other materials used in medical applications. Let us put our expert team to work on your next project.