What to Know about Complex Masking Requirements in Precision Machinin

When shops quote customers high costs and long lead times for anodized parts, often it’s because the masking requirements are exceedingly complex. In some cases, complex masking requirements can double the price of a part.

Keep reading for our AS9100 machine shop’s insights into complex masking and tips for getting your parts faster and more cost-effectively.

Complex Masking = Higher Costs and Longer Lead Times

Masking is an entirely manual process that requires meticulous attention to detail. Flat, smooth surfaces are easy enough to mask. But when it comes to masking only a portion of a surface or small and intricate features, the process can be surprisingly time-consuming.

We once sent a lot of 15 parts to our trusted plating vendor, and it took them all day to mask just three parts. That’s not because the person doing the masking was slow or bad at their job. On the contrary, it’s because they’re great at their job and willing to put in the time and effort required to get it done right.

Since time is money in manufacturing, complex masking can add significantly to the cost per part. In this particular case, the plating vendor charged $300 per piece for the masking alone.

It’s worth noting that complex masking requirements can also cause delays during the quoting phase of a precision machining project. It can take an extra couple of days for a machine shop to receive an accurate estimate from a plating vendor.

Consider Chem Film to Avoid Complex Masking

As an AS9100 machine shop, we receive many anodizing requests from aerospace and space customers. Anodizing seals the surface of an aluminum part, providing a durable, corrosion-resistant coating that can withstand significant wear in extreme environments.

Because an anodized coating is electrically non-conductive, some of our space customers want certain features masked to maintain conductivity. While this request is completely valid, we like to encourage these customers to consider a chem film coating as an alternative to anodizing.

Like anodizing, chem film seals an aluminum surface and protects it from corrosion and wear. However, unlike anodizing, chem film helps conduct electricity. In other words, by selecting chem film over anodizing, space customers enjoy most of the benefits of anodizing without having to worry about costly and time-consuming masking.

Simplify Masking Requirements When Possible

We understand that customers whose parts require superior durability and wear resistance may not have the option of choosing chem film. In these cases, there are steps to take to simplify masking requirements.

When your objective is maintaining electrical conductivity, we recommend plugging threaded holes. It’s possible to achieve electrical conductivity through a threaded hole. And inserting a rubber plug into a hole is easier (i.e., faster and more cost-effective) than masking an intricate feature.

Another best practice is to mask large, smooth, flat surfaces instead of intricate features.

When You Need Complex Masking, Trust Our AS9100 Machine Shop

Can’t avoid complex masking? Don’t worry—Focused on Machining will make it happen. We just like to set clear expectations with customers about how complex masking can affect costs and lead times. It’s always a good idea to plan these projects well in advance.

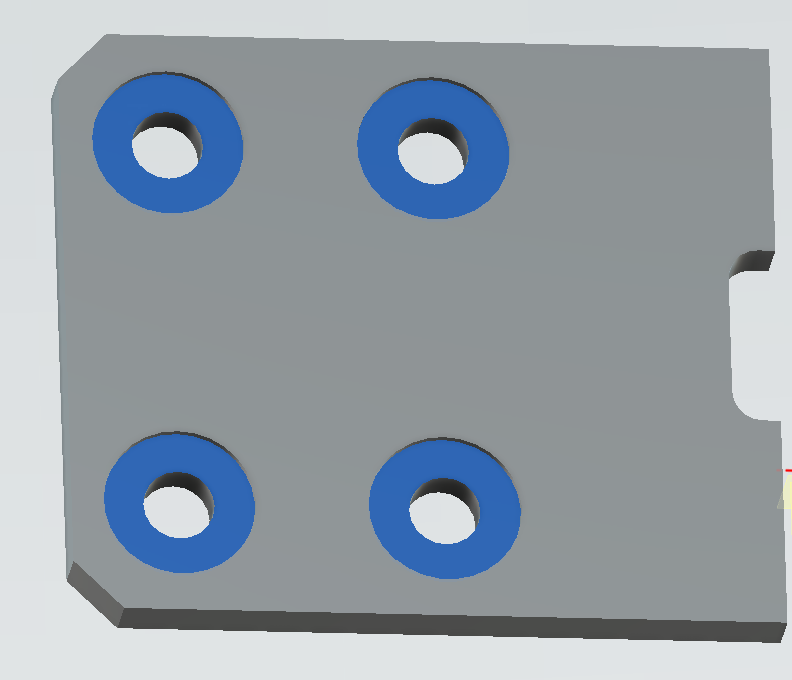

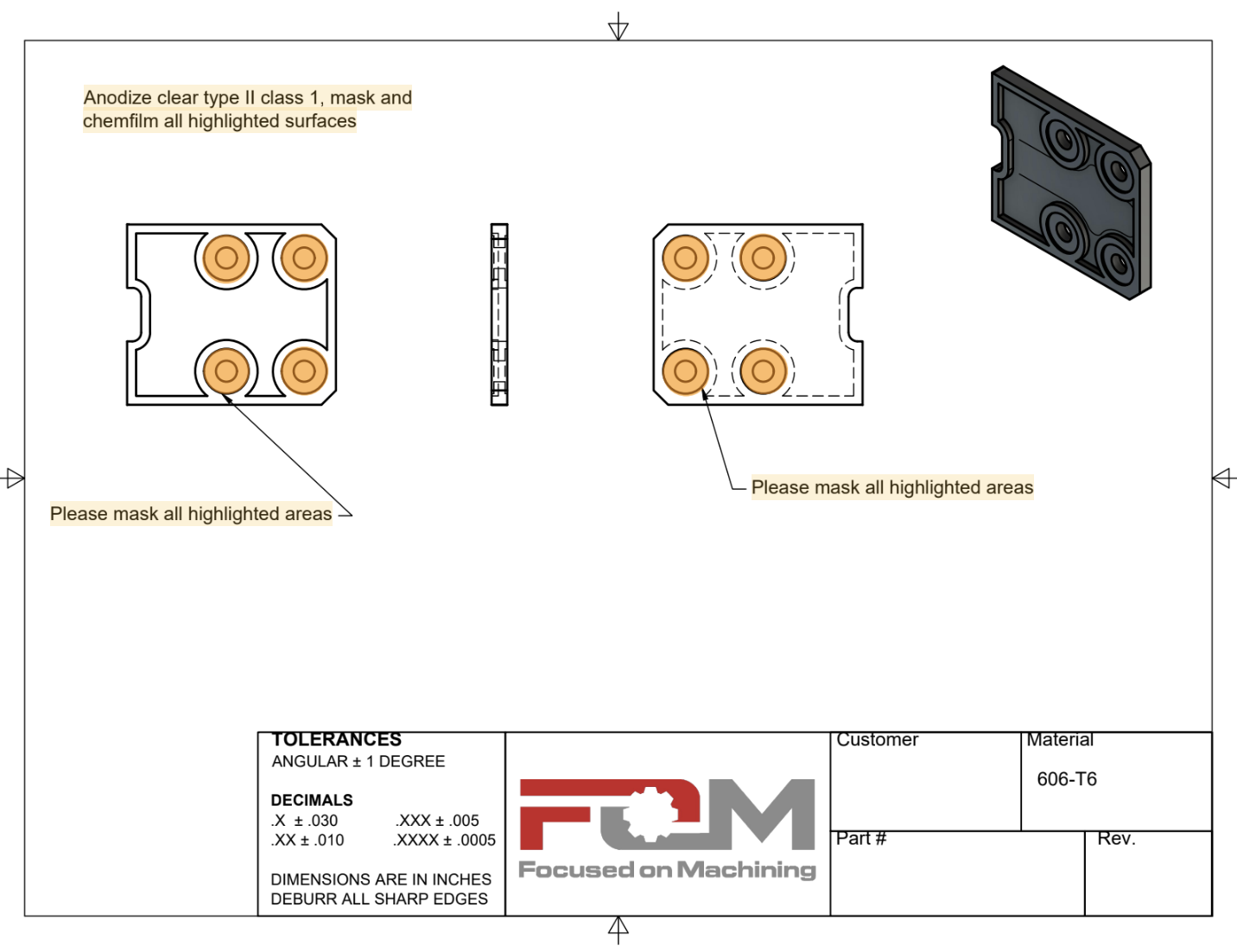

We have solid partnerships with some of the best plating shops in the country, and these shops specialize in complex masking. Over the years, we’ve refined our method for communicating complex masking requirements to plating partners. Our standard is to create our own masking prints that highlight areas requiring masking to make their jobs as easy as possible.

Request a quote from our AS9100 machine shop today!