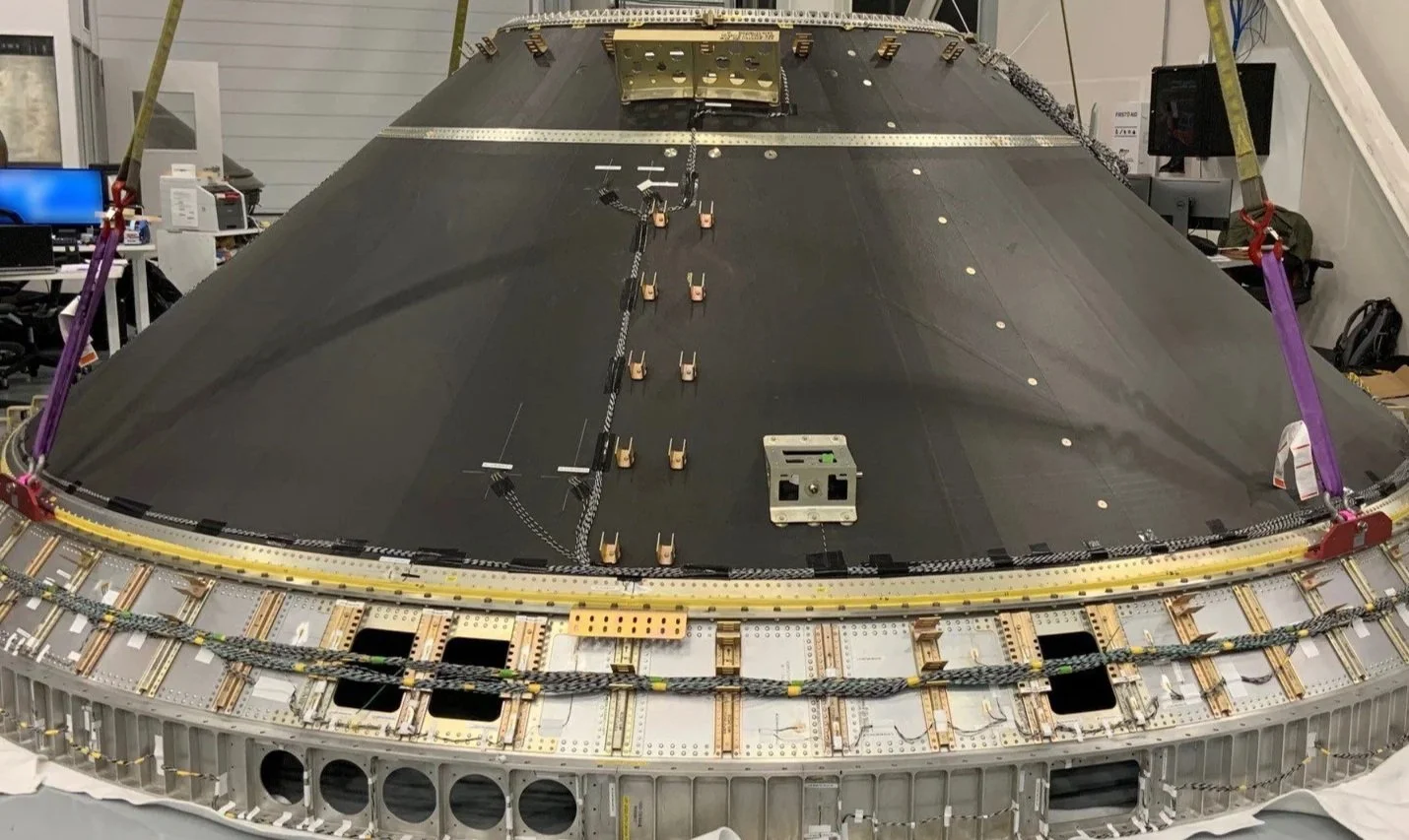

Proven on ULA Vulcan Centaur — Ready for Blue Origin, SpaceX, and LEO Constellations

Mission-Critical Machining

for Launch Vehicles & Orbital Systems

Precision-machined aluminum components for multi-payload dispensers and stage separation — proven on ULA Vulcan Centaur, built for Starship-class vehicles and LEO constellation deployment systems.

Our Space-Grade Expertise

- 5-axis milling of aluminum, titanium, and Inconel

- Space compatible finishes and Sub-assembled components

- Contract Manufacturing at small batch and full rate production

- Full material traceability and AS9100D / ITAR / CMMC Level 2 compliance

- Veteran-owned with direct launch-vehicle supply-chain experience

Built for Mega-Constellations

Repeatable, zero-defect machining for satellite buses, solar-array brackets, propulsion mounts, and dispensers.

From 10 prototypes to 10,000 flight units — we scale with Starlink, Kuiper, and next-gen LEO programs.

Space Machining Insights

Technical deep-dives on materials, 5-axis techniques, and compliance for launch vehicles and orbital systems.

Ready to Launch Your Next Program?

AS9100D | ITAR Registered | CMMC Level 2 | Service-Disabled Veteran-Owned

REQUEST A SECURE QUOTE

Photography of representative flight hardware courtesy of United Launch Alliance. Used with permission.