Why 3D Models Are Important in Precision Machining

When requesting a quote for precision machining services, it’s in your best interest to include a 3D model in addition to a blueprint.

Both documents combined tell the complete story about a part, ensuring that customers get exactly what they need quickly and cost-effectively. Let’s explore why models are so crucial in precision machining.

Models Provide Critical Context to Ensure Part Accuracy

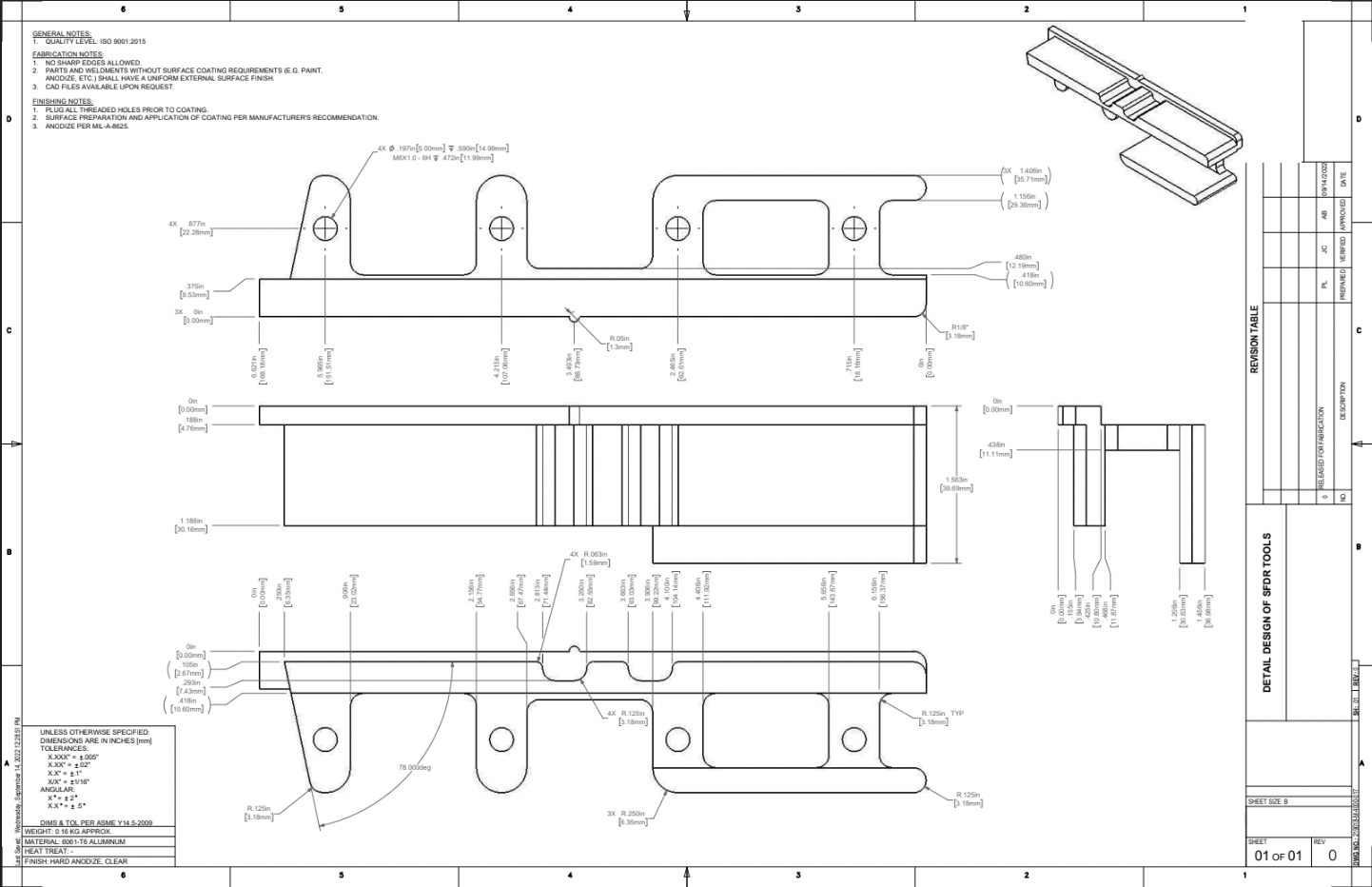

A blueprint provides essential details about a part’s features and each feature’s precise specifications. A model provides additional context that helps to clarify interpretive statements on the blueprint.

For example, an engineer might leave a note in the blueprint to “break all sharp edges.” However, the machinist’s interpretation of an edge break may differ slightly from the engineer’s. As a result, the engineer might not get precisely what they wanted.

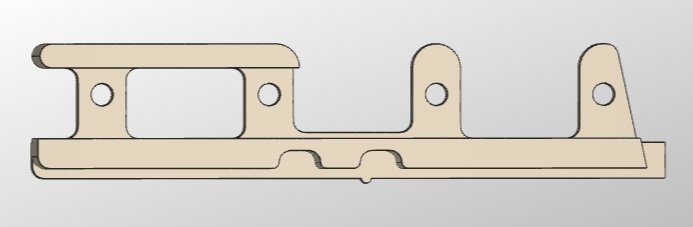

In contrast, programming edge breaks into the model eliminates guesswork, giving machinists a clear 3D visual to add context to the specification from the blueprint.

3D Models Streamline Manufacturing to Improve Lead Times

Providing precision machine shops with a model in addition to a blueprint may feel needlessly cumbersome. But it actually streamlines manufacturing significantly, which is vital to many prototype machining customers seeking quick-turn manufacturing services.

Quick quoting

3D models empower us to turn around fast quotes using our digital quoting software. The software analyzes the model and automatically tells us important information about a part so that we can provide an accurate quote and get your project moving.

Simple programming

Our CNC machines and CMM inspection software use models to achieve auto-programming. For example, when it’s time to program a machine for a manufacturing operation, we can upload the model, click the features, add the tool paths, and get the operation started quickly.

Models Save Customers Money

We don’t machine parts without a model at Focused on Machining, so when a customer can’t provide a model, we need to create one in-house.

In these cases, we charge for our engineering time, which includes going back and forth with the customer over the course of a few days to make sure we’re interpreting the information on the blueprint accurately.

Our Advice: Always Include a 3D Model

For these reasons, we always encourage customers to provide models when requesting a quote for our precision machining services. We’re even happy to connect you with a freelance engineer who will develop a model for you at a fair rate!

We realize that some buyers have difficulty convincing engineers to grant them access to models. If you’re in this situation, it’s worth having a conversation with your engineering team. Be clear about how the absence of a model can negatively impact cost, lead time, and even quality.

Ready to get your project started? Request a quote from Focused on Machining—and don’t forget to include a 3D model if possible!