BLOG

A Shop You Can Trust for Inconel Machining

Looking for a Denver machine shop that excels at Inconel machining? At Focused on Machining, we love working with challenging materials that many other job shops try to avoid. Titanium and Nitronic 60 are examples of materials that get us excited to come to work every morning, but one material that’s hard to top is Inconel.

Looking for a Denver machine shop that excels at Inconel machining?

At Focused on Machining, we love working with challenging materials that many other job shops try to avoid. Titanium and Nitronic 60 are examples of materials that get us excited to come to work every morning, but one material that’s hard to top is Inconel.

Known for its exceptional resistance to corrosion and high temperatures as well as its superior pressure tolerance, Inconel is an ideal material for aerospace machining. It doesn’t move or expand with the introduction of extreme heat, which is why you’ll often see it used for jet engine components.

But the same properties that make Inconel such a desirable material also make it extremely difficult to machine. Like titanium, Inconel is prone to work hardening, which increases the risks of tool wearing and potentially compromises part quality.

Today, we’ll review some of the most common grades of Inconel and explore why Focused on Machining is your go-to shop for Inconel machining.

Common Grades of Inconel

There are more than 20 metal alloys in the Inconel family, but here are several of the most common ones:

Inconel 600. This versatile engineering material has exceptional heat-resistant and corrosion-resistant properties. From a mechanical standpoint, it combines both high strength and excellent workability. It’s capable of withstanding temperatures ranging from cryogenic to above 2,000 degrees Fahrenheit. Inconel 600 is ideal for pharmaceutical applications (bubble towers, heaters, stills), nuclear reactors, and engine and airframe components.

Inconel 617. This grade of Inconel is known for its high-temperature strength, oxidation resistance, and corrosion resistance. Inconel 617 is common in gas turbine components like transition liners, combustion cans, and ducting due to its ability to maintain high strength and oxidation resistance at temperatures exceeding 1,800 degrees Fahrenheit.

Inconel 625. The unique combination of chemical elements in Inconel 625 yields high strength and superior corrosion-resistant properties in temperatures ranging from cryogenic to 1,800 degrees Fahrenheit. This grade of Inconel is a great choice for applications like reaction vessels, tubing, and heat exchangers that need to be strong and capable of withstanding corrosive environments.

Inconel 690. With its high level of chromium, Inconel 690 can successfully resist oxidizing chemicals and high-temperature oxidizing gases. The substantial nickel content ensures exceptional resistance to stress-corrosion cracking, enabling it to hold up well to chloride and sodium hydroxide. Inconel 690 is common in applications where nitric acid and nitric/hydrofluoric acid are present, such as tail-gas reheaters and heating coils. It’s also ideal for applications that process sulfuric acid.

Inconel 718. This age-hardenable alloy has high strength and corrosion-resistant properties and can withstand temperatures ranging from -423 degrees Fahrenheit to 1,300 degrees Fahrenheit. From a manufacturing standpoint, Inconel 718 is known for being relatively easy to work with and even stands up exceptionally well to welding. It’s the preferred Inconel grade for various applications, including components for gas turbine engines, fasteners, and instrumentation parts.

Inconel X-750. This precipitation-hardenable grade of Inconel possesses high strength, oxidation resistance, and corrosion resistance at temperatures ranging from cryogenic to 1,300 degrees Fahrenheit. It maintains exceptional strength up to 1,800 degrees Fahrenheit with heat treating. Inconel X-750 is common in applications such as gas turbines, rocket engine thrust chambers, airframes, extrusion dies, forming tools, springs, and fasteners.

Inconel Machining at Focused on Machining

When you need Inconel machining for your aerospace applications, you need an AS9100 machine shop like Focused on Machining that does what it takes to crack the code on challenging materials.

In recent years, 3D printing has become increasingly popular for Inconel parts with complex geometries, such as a design requiring internal cooling channels. While this is an ideal use case for 3D printing, precision machining remains the optimal choice for simpler components. For instance, when manufacturing parts such as plugs, bushings, or washers that require tight tolerances, machining is often more efficient than 3D printing.

In addition, machining can often be faster for many parts than 3D printing. While 3D printing can produce parts quickly, the required post-processing steps often significantly increase lead times. Machining, by contrast, often provides a more direct path to a finished part, resulting in overall faster delivery times.

Many of the Inconel alloys we work with have gone through an annealing process that alters the material properties to increase ductility and reduce hardness. In these cases, we can use our standard tooling and the special tooling we already have on hand for hard materials while carefully monitoring feeds and speeds during machining. However, if we’re cutting heat-treated Inconel, we need to use custom ceramic tooling that won’t break easily.

We typically passivate Inconel parts post-machining to remove iron and other impurities from the surface and produce a protective oxide coating that further resists corrosion.

We’re thrilled to be working on some exciting Inconel parts right now and can’t wait to take on more of these projects. Request a quote for Inconel machining today!

Frequently Asked Questions

Is Inconel difficult to machine?

Inconel is challenging to machine due to its work hardening, high cutting forces, heat generation, and susceptibility to workpiece deflection, leading to tool wear and dimensional inaccuracies.

Does Inconel 718 rust?

Inconel 718 resists corrosion in seawater but may corrode in extreme marine conditions like high salinity, elevated temperatures, and high chloride levels

Is Inconel stronger than titanium?

Both Inconel and titanium are very strong, but titanium is generally considered stronger, especially at high temperatures. Titanium is also much lighter than Inconel, making it a better choice for weight-sensitive applications, such as in the aerospace industry.

Why is Inconel so expensive?

Inconel is expensive due to its high nickel and chromium content, both costly metals. Its premium alloy properties, including excellent corrosion resistance and high-temperature tolerance, justify the price for demanding applications. Nickel supply fluctuations can also impact its cost.

6 DFM Tips for CNC Turned Parts

Want better, faster, and less expensive CNC turned parts from your precision machining partner? At Focused on Machining, we provide CNC turning services at whatever level your project demands. We consistently turn parts to precise tolerances using sophisticated equipment and our extensive breadth of tooling.

Updated for April 2025

Want better, faster, and less expensive CNC turned parts from your precision machining partner? At Focused on Machining, we provide CNC turning services at whatever level your project demands. We consistently turn parts to precise tolerances using sophisticated equipment and our extensive breadth of tooling.

Our talented lathe operators can machine almost any part that comes our way. Still, there are cost and time-saving considerations that we want our customers to know about.

Today, we’ll review 6 Design for Manufacturing (DFM) best practices to help you get the highest quality CNC turned parts quickly and cost-effectively.

6 Time and Cost-Efficient Considerations for CNC Turned Parts

1. Add allowances when designing for stock material specifications

Engineers will often design CNC turned parts as closely as possible to stock material specifications under the assumption that they’ll save on material costs and machine time. The problem with this approach is that the sizing for bar stock can vary up to 10%.

If, for instance, your part needs to measure close to ½”, then ½” bar stock may not be a viable option. Instead, we’ll need to size up to ⅝” or even ¾” bar stock to account for any dimensional variance.

Another important consideration is material straightness. Even with correctly sized stock material, bars can have slight bends or warping, and we may not have enough material to clean up the entire surface.

If costs are a major concern for you and you want us to order the minimal amount of bar stock, be sure to add adequate allowances when designing for stock material specifications.

2. Note “stock finish okay” on your print if applicable

Stock material can become damaged during transit, arriving with gouges, scratches, and other imperfections. At our Colorado machine shop, we always machine the external surfaces of the parts we make to improve the appearance of the surface finish—unless instructed otherwise.

If a stock finish is acceptable for your CNC turned part, let us know by indicating “stock finish okay” on your print. We’re happy to leave the outside of the part untouched if you only need internal features, and requesting a stock finish can save you up to 75% on the cost of your project.

3. Indicate if a center mark is permissible or not

If your CNC turned part is longer than it is round and is longer than 4 inches, we may need to engage the tailstock inside the lathe to support the part on both ends instead of just one. This technique creates a more rigid structure, allowing us to turn more features, hold tighter tolerances, and produce higher volumes faster. However, it does leave a small center mark behind where the tailstock enters the part.

The center mark may or may not be a problem depending on the part, but this determination is ultimately up to the customer. If it’s not permissible, we’ll need to complete an additional operation to remove it, which will affect cost and lead time.

Be sure to let us know up front whether a center mark is permissible or not so we know how to proceed.

4. Factor in corner radii

It’s possible for us to machine sharp corners in CNC turned parts, but doing so requires special (i.e., expensive) tooling. Even then, the tooling is prone to chipping and breaking.

A cost-effective alternative is to include a radius wherever two faces intersect to eliminate 90-degree turns. That way, we can use our standard tooling. A simple rule of thumb is to design radii measuring a minimum of .008”, but keep in mind that the larger the radius, the faster we can machine the feature. And we often remind customers: a larger radius in a perpendicular corner actually leads to a stronger part.

5. Avoid over-tolerancing the surface finish

If you were to take a milled part and a turned part directly off of each machine, the turned part would have an exceptionally smooth surface finish, while the milled part would show tooling lines from the end mill. But if you then measured the surface finish of both parts, the turned part would, counterintuitively, have a higher Ra value.

The takeaway is to be mindful of over-tolerancing CNC turned parts because the surface finish often looks much better than the measurement conveys. Extremely tight tolerance specifications may require custom grinding operations, and they can significantly increase cost and lead time in our production machining services. Not only that, high volumes require significantly more labor, as team members must check a large number of parts to ensure they match specifications.

6. Maintain a length-to-diameter ratio of 4X in parts

The further the workpiece is from the workholding, the less rigid and stable it becomes. If, for instance, your part has a length-to-diameter ratio of 10:1, chatter resulting from the tool vibration can compromise tight tolerance machining and surface finish specifications. A part with a 2X length-to-diameter ratio, on the other hand, is exceptionally rigid, allowing for efficient and precise machining.

If your part exceeds the recommended ratio, we can still machine it—our CNC machine shop has the problem-solving ability to deliver on our promises—but we’ll have to use a workaround, like engaging the tailstock to add a center-drilled hole.

Bonus Tip: Aim for a length-to-diameter ratio of 4X in holes

It’s possible to create holes with a greater length-to-diameter ratio than 4X, but the process becomes extremely slow. Essentially, we have to peck out the hole, withdrawing the tool repeatedly to remove the chips. Failing to withdraw the drill creates high heat and pressure that will ultimately break the drill, resulting in costly delays.

When you need a precision machining partner for your CNC turned parts, our precision machine shop is here to deliver. Contact us today, and let’s discuss optimizing your design for CNC turning services.

Innovative Applications for Custom Picatinny Rails

One frequent and rewarding project we handle is machining picatinny rails for major OEM firearms manufacturers. We enjoy the technical requirements and repeatability involved in machining these parts, and we are well-equipped to support high-volume production runs for commercial and military applications alike.

At Focused on Machining, we partner with customers in a wide range of industries to deliver high-quality machining, specializing in high-volume production machining services for a wide variety of parts. From aerospace to defense to general components, our precision machine shop meets the highest standards in every project we take on, backed by industry-leading service and support.

One frequent and rewarding project we handle is machining picatinny rails for major OEM firearms manufacturers. We enjoy the technical requirements and repeatability involved in machining these parts, and we are well-equipped to support high-volume production runs for commercial and military applications alike.

Image courtesy of bulletcentral.com

Image courtesy of pacifictoolandgauge.com

Picatinny Rails for Firearms

A picatinny rail is a mounting bracket—commonly made from black anodized aluminum—that attaches to the receiver, fore-end stock, or handguard of a firearm. When this simple product hit the market, it opened up a whole new world of mounting possibilities for firearms users.

Originally designed to mount scopes, picatinny rails evolved to hold many other accessories, from laser sights and tactical lights to night vision devices and bayonets. This simple yet robust design can make accessory attachment faster and more secure.

Today, the use of picatinny rails often extends into interesting and innovative civilian applications. While we do not specialize in consumer-grade or low-volume work, our focus is on supporting high-precision, production-scale machining for commercial and industrial markets.

Picatinny Rails Manufacturing at Focused on Machining

At our Denver machine shop, we machine picatinny rails on our horizontal mills. Leveraging our lights out manufacturing capabilities, we run these parts quickly at high volumes of up to 15,000 pieces per year. Our contract manufacturing services can be ideal for volumes like this, and customers can see a variety of benefits:

Cost savings: By arranging for high volumes in a contract, costs will be reduced in several ways. For instance, setup expenses are distributed across more parts, and tooling can be planned for well in advance.

Consistent quality: Quality is critical for law enforcement parts, and by staying with the same manufacturer for high volumes across several years, you’ll ensure the same high-level quality with each delivery.

Simplified process: By reducing your administrative work and having the same manufacturing partner as a single point of contact, you can streamline your entire manufacturing experience.

Picatinny rail designed to mount a light to the handlebar of a bicycle. Image credit: Scout Cycling Products

Picatinny rail designed to mount mirrors on a Jeep Wrangler. Image credit: Offroad Elements

Picatinny rail designed to mount a GoPro onto a drone. Image credit: Gimbal-Guard

Picatinny rail designed to mount headborne accessories to a helmet. Image credit: Team Wendy

Partner With Our Expert Shop for Picatinny Rails

We’re honored to work with top OEM firearms manufacturers and are ready to machine picatinny rails for other commercial needs as well, such as military or law enforcement applications. And our expertise in machining picatinny rails is just one example of our broader commitment to precision manufacturing.

Whether we’re working with 6061 aluminum or challenging materials like Inconel or titanium, our team thrives on complex parts and tight tolerances. We maintain rigorous quality control standards across every job, from first article inspection to final delivery.

Whatever you need in your next project, we’re ready to take on the challenge! Request a quote and let’s get the conversation started. Our Colorado machine shop is ready to make your idea into a reality!

7 Reasons to Work with Our AS9100 Machine Shop

Remember when we shared that we were in the process of getting AS9100 certified? Well, we’re thrilled to announce that Focused on Machining is now officially an AS9100 machine shop!

Top Shops data indicates that only 45% of machine shops have quality certifications like ISO 9001 and AS9100, and we’re proud that our Denver machine shop is part of this elite group.

Remember when we shared that we were in the process of getting AS9100 certified? Well, we’re thrilled to announce that Focused on Machining is now officially an AS9100 machine shop!

Top Shops data indicates that only 45% of machine shops have quality certifications like ISO 9001 and AS9100, and we’re proud that our Denver machine shop is part of this elite group.

Being AS9100 certified means that we follow a strict set of quality management system requirements to ensure that we provide safe and reliable parts to aerospace customers.

We already have loads of experience machining aerospace prototypes. But this certification will allow us to deepen our relationships and work with customers on low-volume production runs as well.

How Customers Benefit from Working with Our AS9100 Machine Shop

Customers across all industries benefit from working with an AS9100 machine shop. In preparation for this certification, we’ve honed our processes and operations to provide better service than ever. Here’s what you can expect from Focused on Machining:

Comprehensive documentation. Formal inspection reports are an industry standard for aerospace. But no matter what industry you’re in, your parts will benefit from going through our full quality process. Rather than limiting this process to only the customers who require inspection data, we conduct inspections and formally document the results for each part we machine. We also generate first article inspection (FAI) reports as part of this process.

Formal PO confirmations. When we confirm a date and price to a customer, we’re dead set on delivering on those promises no matter what. Before confirming a PO, we conduct due diligence to verify things like material pricing and availability and overall project timeline. Our goal is to always negotiate upfront with customers instead of flying by the seat of our pants and having to negotiate on the back end.

Part tracking. With the click of a button, our comprehensive ERP system tells us exactly where a part is in the manufacturing process—whether it’s in machining, inspection, outside processing, or ready to ship. We can provide full visibility into anything from the amount of time spent on the part to the machine it’s currently on. All you have to do is ask.

Detailed box labels. We take pride in our box labels, which include a clear image of the part and key details like revision number, work order number, quantity, and more. Many customers have told us that these box labels help streamline their own receiving processes. One customer even uses our packaging as part of their inventory system because it has all the information they need.

No paper trails. We store all data digitally in our secure ERP system. You never have to worry about your proprietary information floating around our shop.

Serialization. An increasing number of customers have been asking us to serialize their parts and we’re more than happy to deliver. Our machinists track and number each part sequentially and can even laser engrave part numbers at your request.

Faster turnaround. As a result of our streamlined processes, we’re working more efficiently than ever before. Although material shortages are slowing down everyone in manufacturing right now, we remain committed as ever to our promise of high-quality CNC machined parts when YOU need them.

For us, the best thing about being an AS9100 machine shop is that it gives us the opportunity to take on more of the aerospace machining projects we love most—from complex titanium parts to internal and external components for Nitronic 60 minisatellites.

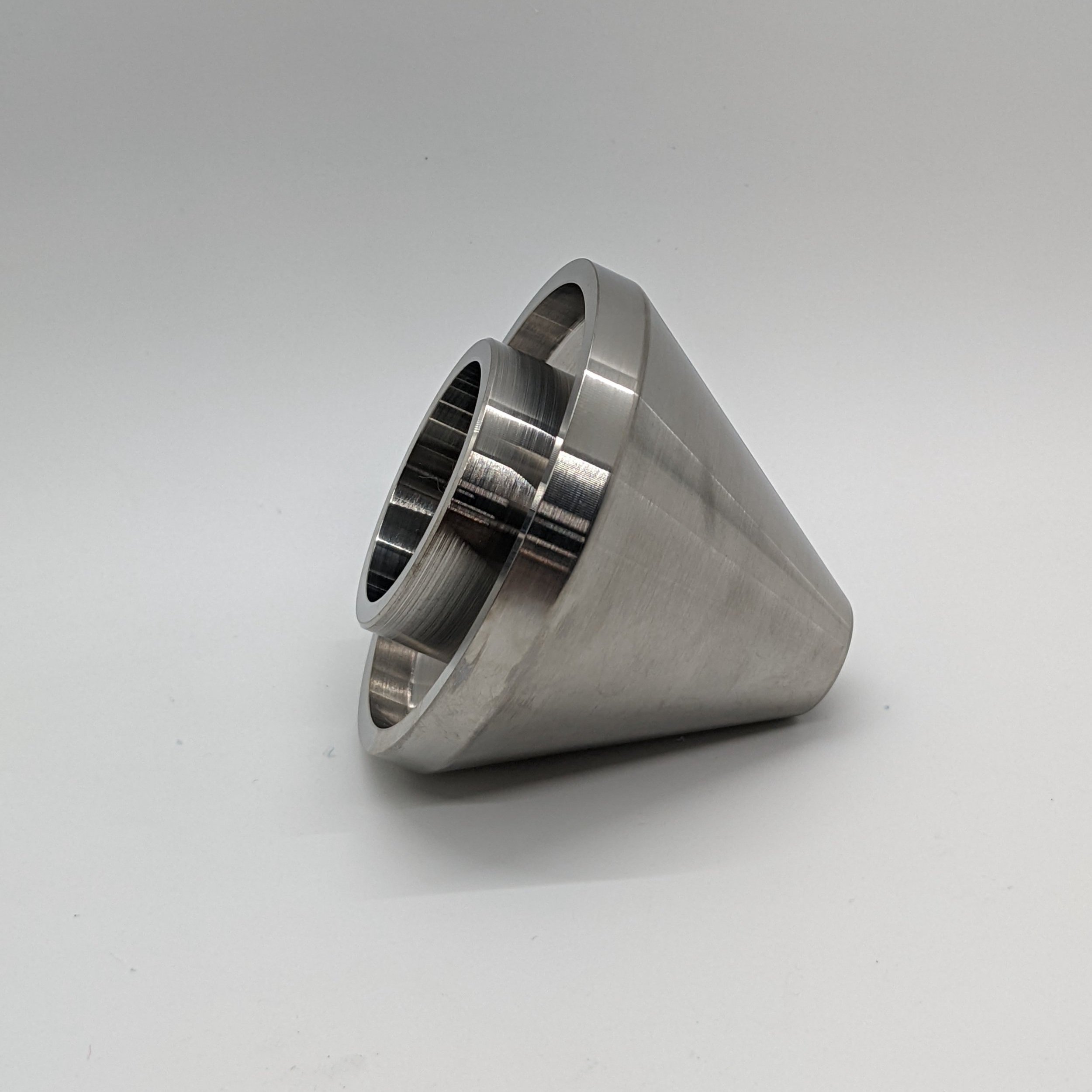

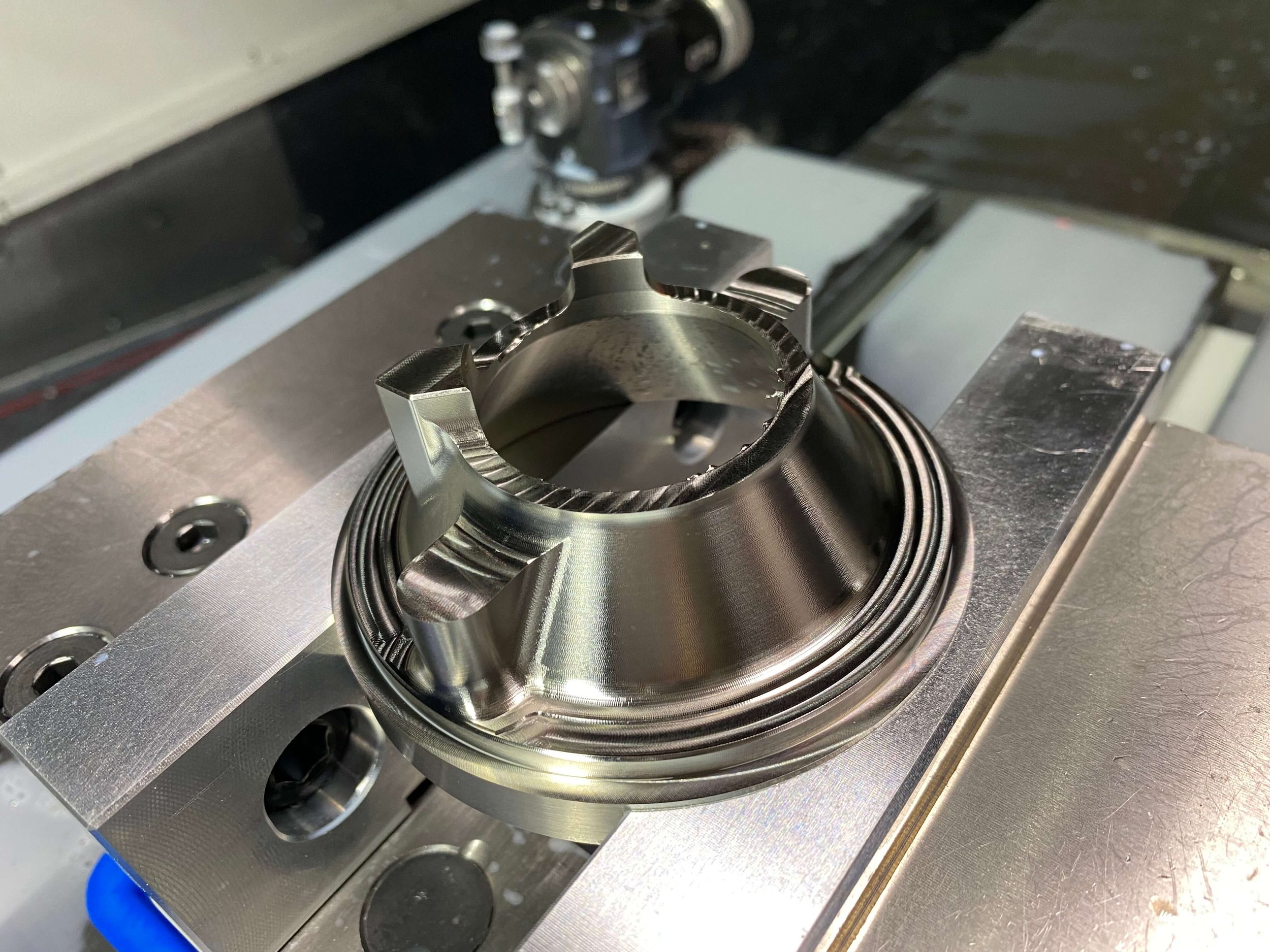

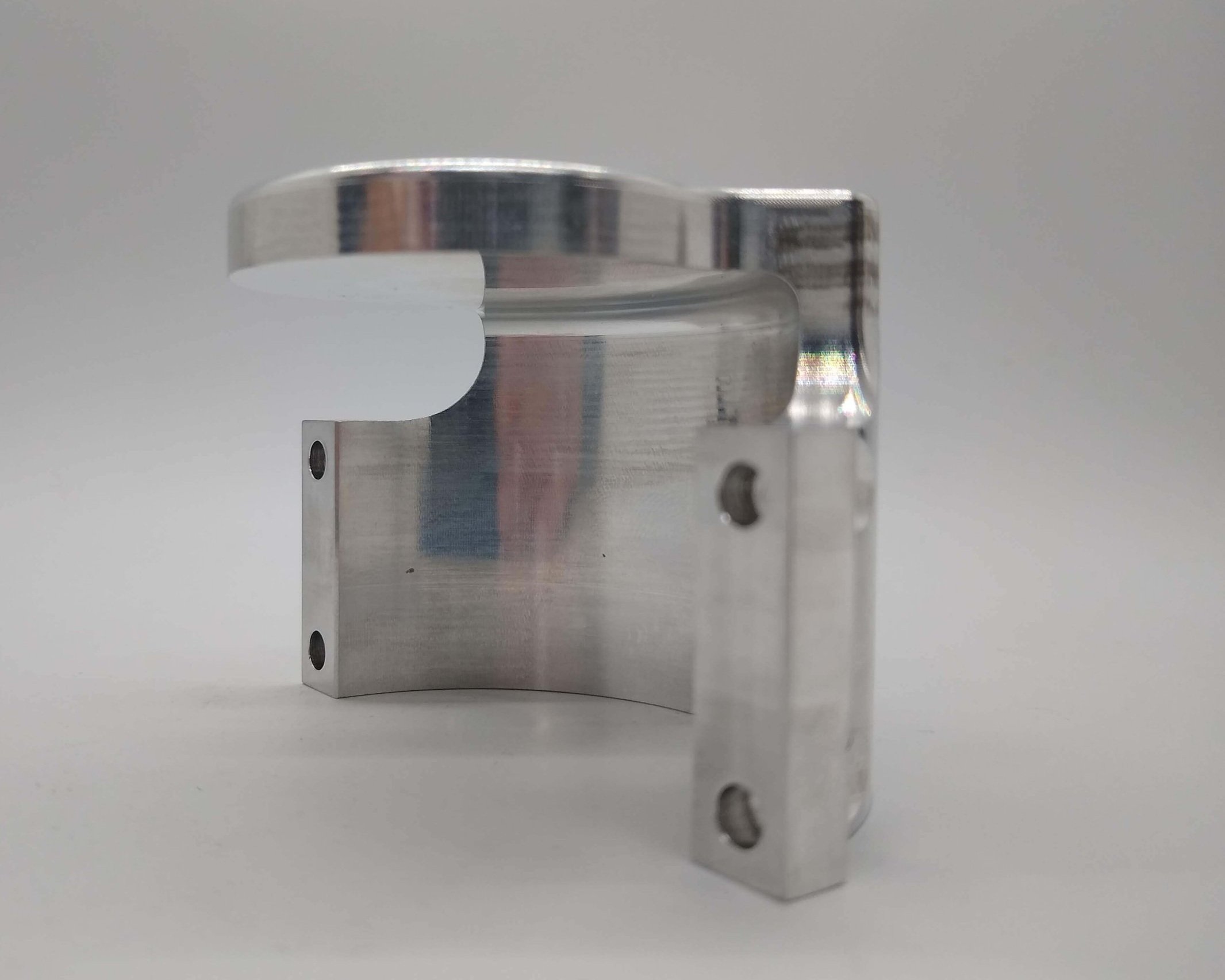

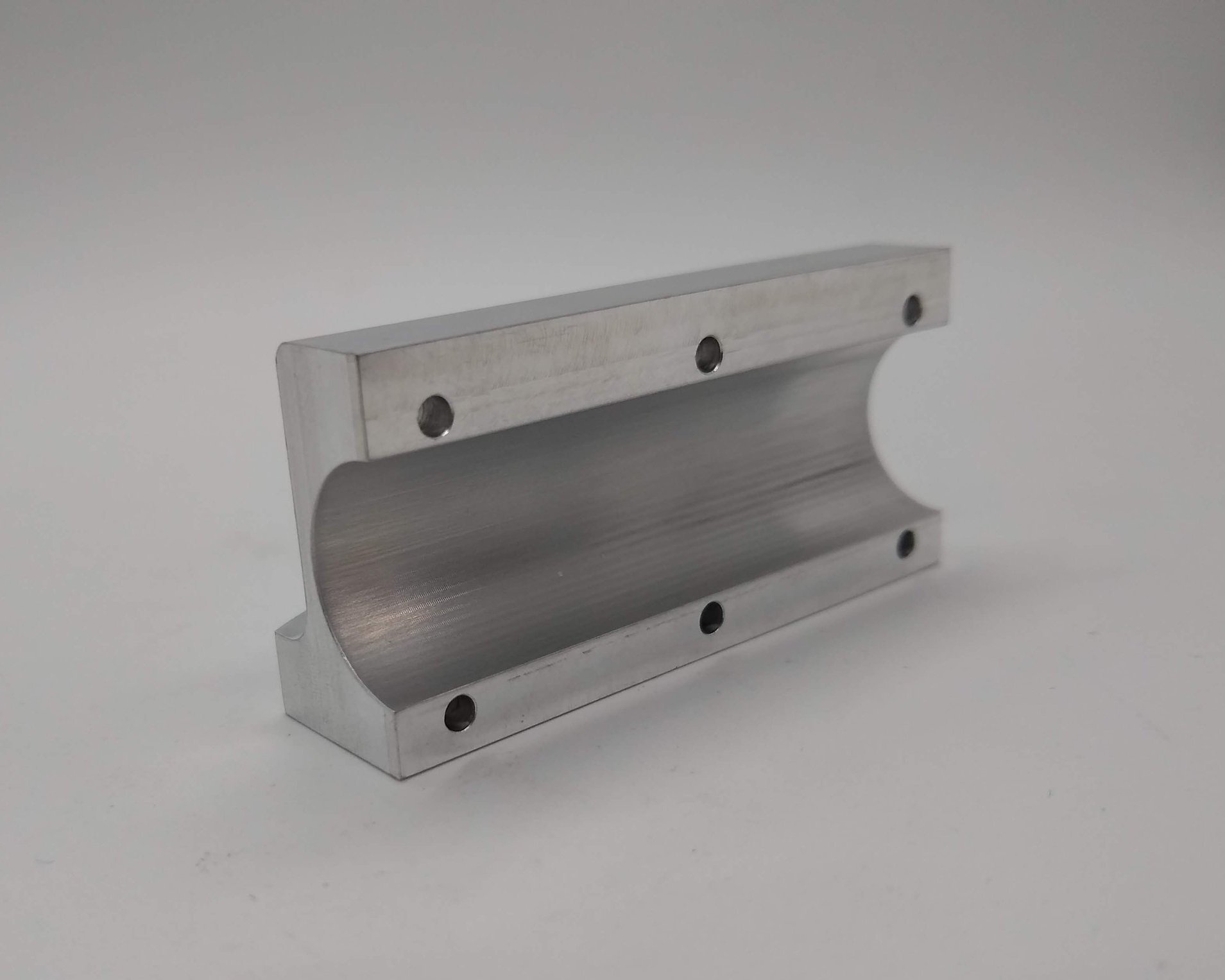

Here’s a look at some of the aerospace parts we’ve made recently:

Focused on Machining is ready and excited to put our aerospace machining expertise to the test for you. If you’re looking for a reliable AS9100 machine shop, we hope you’ll trust us with your part.

Nitronic 60 Stainless Steel: The Next Frontier in Space Materials

At Focused on Machining, we’re always up for the next challenge that comes our way. From cracking the code on titanium machining to pursuing AS9100 certification, we’re masters of complexity and difficulty in all aspects of our precision CNC machining services.

At Focused on Machining, we’re always up for the next challenge that comes our way. From cracking the code on titanium machining to pursuing AS9100 certification, we’re masters of complexity and difficulty in all aspects of our precision CNC machining services.

When confronted with a new material, our philosophy is always this: just because we’ve never cut it before doesn’t mean we won’t. So when quotes for Nitronic 60 parts started hitting our inbox, we jumped at the opportunity to work with this innovative material that’s generating a lot of buzz in the space industry.

Now, we’re well-versed in the intricacies of Nitronic 60 machining. Through our experience and our investment in optimal tooling, we’re able to maximize speed and precision, always delivering excellent results.

What Is Nitronic 60? Nitronic 60 is an all-purpose stainless steel alloy fortified with silicon and manganese to provide these key benefits:

High corrosion resistance. Nitronic 60 has corrosion resistance properties comparable to 304 and 316 stainless steels while offering nearly twice the yield strength.

Minimal wearing, galling, and fretting. The addition of silicon and manganese gives this material superior wear-inhibiting properties compared to other types of stainless steel. While threaded 304 stainless steel parts tend to gall and grip onto each other, Nitronic 60 parts go together much more smoothly, making it popular for helical thread inserts in high-performance applications such as aerospace.

Temperature performance. Nitronic 60 maintains its mechanical properties across a wide temperature range, including extremely elevated temperatures.

These benefits are especially important in space applications, where parts are continually subjected to extreme environments and temperature changes. Our extensive aerospace machining experience ensures we can manufacture Nitronic 60 components to the exacting requirements of space applications.

The choice between Nitronic 60 and other high-performance materials depends on the specific demands of the application. For instance, in cases where galling resistance is critical, Nitronic 60 often outperforms alternatives like Alloy 333. However, applications prioritizing corrosion resistance might call for 316 stainless steel (also known as "316 surgical steel" for its medical applications), while those requiring exceptional high-temperature performance might be better served by Inconel 718.

Whatever your material requirements, our team at Focused on Machining brings extensive experience to every project, including specialized expertise in Inconel machining.

At Focused on Machining, we’re always up for the next challenge that comes our way. From cracking the code on titanium machining to pursuing AS9100 certification, we’re masters of complexity and difficulty in all aspects of our precision CNC machining services.

When confronted with a new material, our philosophy is always this: just because we’ve never cut it before doesn’t mean we won’t. So when quotes for Nitronic 60 parts started hitting our inbox, we jumped at the opportunity to work with this innovative material that’s generating a lot of buzz in the space industry.

Now, we’re well-versed in the intricacies of Nitronic 60 machining. Through our experience and our investment in optimal tooling, we’re able to maximize speed and precision, always delivering excellent results.

What Is Nitronic 60?

Nitronic 60 is an all-purpose stainless steel alloy fortified with silicon and manganese to provide these key benefits:

High corrosion resistance. Nitronic 60 has corrosion resistance properties comparable to 304 and 316 stainless steels while offering nearly twice the yield strength.

Minimal wearing, galling, and fretting. The addition of silicon and manganese gives this material superior wear-inhibiting properties compared to other types of stainless steel. While threaded 304 stainless steel parts tend to gall and grip onto each other, Nitronic 60 parts go together much more smoothly, making it popular for helical thread inserts in high-performance applications such as aerospace.

Temperature performance. Nitronic 60 maintains its mechanical properties across a wide temperature range, including extremely elevated temperatures.

These benefits are especially important in space applications, where parts are continually subjected to extreme environments and temperature changes. Our extensive aerospace machining experience ensures we can manufacture Nitronic 60 components to the exacting requirements of space applications.

The choice between Nitronic 60 and other high-performance materials depends on the specific demands of the application. For instance, in cases where galling resistance is critical, Nitronic 60 often outperforms alternatives like Alloy 333. However, applications prioritizing corrosion resistance might call for 316 stainless steel (also known as "316 surgical steel" for its medical applications), while those requiring exceptional high-temperature performance might be better served by Inconel 718.

Whatever your material requirements, our team at Focused on Machining brings extensive experience to every project, including specialized expertise in Inconel machining.

The Growing Demand for Nitronic 60 Minisatellites

Nitronic 60 is commonly found in minisatellites, which are popular right now in the space industry. With private companies like SpaceX, Blue Origin, and Virgin Galactic enmeshed in a modern-day space race, there’s a unique opportunity for these toaster-sized minisatellites to hitch a ride into space for much cheaper than ever before. Manufacturers of minisatellites are essentially piggybacking on a trip to space that has already been paid for. Pretty smart!

So far, our AS9100 machine shop has made both internal and external components for these minisatellites using Nitronic 60. We also just finished precision machining for a part that will attach to a Mars rover.

If you have any Nitronic 60 projects coming down the pipeline, we hope you’ll consider getting a quote from Focused on Machining. Our appetite for complexity makes us the perfect partner for new and difficult materials that many other machine shops no-quote. We’re also committed to meeting stringent deadlines no matter what it takes.

Request a quote today from our Colorado machine shop for your next Nitronic 60 project!

Frequently Asked Questions

What is Nitronic 60 material equivalent to?

Nitronic 60 offers oxidation resistance comparable to Type 309 stainless steel and significantly better than Type 304 stainless steel. This alloy is renowned for its exceptional resistance to wear and galling.

What is the difference between Nitronic 60 and Inconel?

Nitronic 60 is a high-strength stainless steel known for wear, galling, and corrosion resistance in moderate temperatures. In contrast, Inconel, a nickel-chromium alloy family, excels in extreme heat and oxidation resistance, making it ideal for high-temperature applications like jet engines and turbines.

Can Nitronic 60 be welded?

Nitronic 60 can be welded with standard methods, but proper techniques are crucial. Use Nitronic 60, 309, or 310 fillers for high strength, and low heat input with convex bead profiles to prevent cracking. Avoid excessive weaving to reduce surface cracks.

Is Nitronic 60 magnetic?

Nitronic 60 is a non-magnetic stainless steel with low magnetic permeability, even when cooled to sub-zero temperatures or cold worked.

Cracking the Code on Titanium Machining

At Focused on Machining, we love working with titanium. . . seriously! Challenging jobs are the ones that get us up in the morning excited about coming to work. There’s nothing more satisfying for our team than figuring out how to excel at something really tough. In particular, we specialize in medium and high-volume production machining services for titanium projects.

Last updated July 2025

Tired of machine shops no-quoting you on complex titanium parts? You need a shop that knows what it takes to machine this difficult material.

At Focused on Machining, we love working with titanium. . . seriously! Challenging jobs are the ones that get us up in the morning excited about coming to work. There’s nothing more satisfying for our team than figuring out how to excel at something really tough. In particular, we specialize in medium and high-volume production machining services for titanium projects.

As part of Colorado’s booming aerospace industry—the second-largest in the country!—our precision machine shop is proud to be a go-to manufacturing partner for titanium aerospace parts.

Challenges of Titanium Machining

Let’s take a quick look at why many shops avoid titanium machining:

It’s difficult to source. Most shops have a close network of local vendors that they rely on for purchasing material in standard bar form. Titanium, however, is much more difficult to source. Shops that work with titanium must look beyond local vendors to source the material out of state, often paying for additional expenses like shipping and freight charges and having the material cut to piece size.

At Focused on Machining, we have a variety of suppliers that deal exclusively in titanium, and we are constantly discussing pricing, lead times, and delivery with them to stay on top of the market.It’s difficult to machine. When machine tools aren’t sharp enough, titanium tends to get gummy during machining, which can lead to a problem known as work hardening. The dull tools mush the material, in turn creating friction and added heat—a known enemy of machinists. The introduction of heat makes what’s already a hard material even harder, increasing the risk of tool wear and compromising the quality of a part.

It’s difficult to figure out. Any challenging machining process inevitably comes with a learning curve. Once you crack the code, there’s an element of repeatability that simplifies processes going forward. But the simple truth is that a lot of shops don’t want to invest the time and effort to reach that point.

Why Focused on Machining Excels at Titanium Machining

We’re not like other shops. We’re always bettering ourselves to become better for our customers. Here’s how we cracked the code on titanium machining:

Tooling selection. In precision machining for materials like steel or aluminum, any 3- or 4-flute end mill—new or used—will cut through the metal just fine. But that’s not the case with titanium. When we work with titanium, we use brand new high-performance 5-flute to 7-flute end mills every time. We’ll never throw a used end mill at a machine to cut titanium. This tooling expertise allows us to drastically increase cutting speeds, reaching nearly the same rate as we do with aluminum parts.

Careful monitoring. Since sharp tooling is the key to avoiding work hardening, we monitor machines closely for tool wear—especially when we’re doing production jobs. If necessary, we change the end mill out much earlier than we normally would to ensure consistently sharp cutting.

Updated technology. We’re pushing the envelope on speeds, rigidity, and tooling performance with a fleet of advanced machines less than 10 years old. Our machines are so fast that we can cut titanium almost as quickly as we can cut aluminum. That’s 180”-250” per minute!

Appetite for complexity. Unlike many of our competitors, our Denver machine shop seeks out challenging parts. If two quotes come in at the same time and one of them is a complex titanium aerospace part, you can guess which one we’re more excited about. We enjoy being the solution to our customers’ toughest machining challenges.

Vendor network for outside processes. Our trusted vendor network allows us to connect you with the right match for your project, including access to specialized options like Tiodize processes—proprietary surface treatments similar in function to anodizing that improve wear resistance and corrosion protection. We can even maintain tight tolerances of +/-0.001" after hard anodizing, a challenge requiring trusted vendors and extremely clear communication throughout the process.

Titanium is a critical material for many of the industries we serve, especially aerospace and defense in our work as an AS9100 machine shop. Major projects in the coming years will require substantial quantities of titanium parts, and we're well-positioned to support you as a tier-one OEM supplier.

Next time you need machined titanium parts, save yourself the hassle of a bunch of no-quotes and come to Focused on Machining first. Request a quote today!