One of the most important truths in manufacturing is that you get what you pay for—from production machining services to secondary processes like plating. Just as machine shops' costs and lead times vary depending on capabilities, certifications, and quality, so is the case for plating vendors.

Why Our Precision Machine Shop Loves Source Inspections

Many shops view source inspections as a necessary evil. Source inspections can indeed be cumbersome for shops whose processes are still mostly manual—there’s no denying that. Fortunately, at Focused on Machining, our robust ERP system allows us to facilitate source inspections easily. In fact, we’ve even come to really appreciate source inspections and the customers who require them.

Could You Benefit from Contract Manufacturing Services?

Reducing the costs of machined parts can be as easy as having a conversation: always communicate with a shop about your purchasing intentions. If you plan to place a particular order on a recurring basis, the right contract manufacturing services partner can talk to you about opportunities to obtain the best costs over time with a long-term contract.

You Get What You Pay for in Manufacturing

You get what you pay for in manufacturing. Unfortunately, many buyers learn this lesson the hard way—something we’ve seen firsthand at our AS9100 machine shop. We’re happy to work with buyers now to get them the parts they need. But imagine the time, money, and stress they could have saved by having us machine their parts in the first place.

The Importance of Investing in a High-Quality Prototype

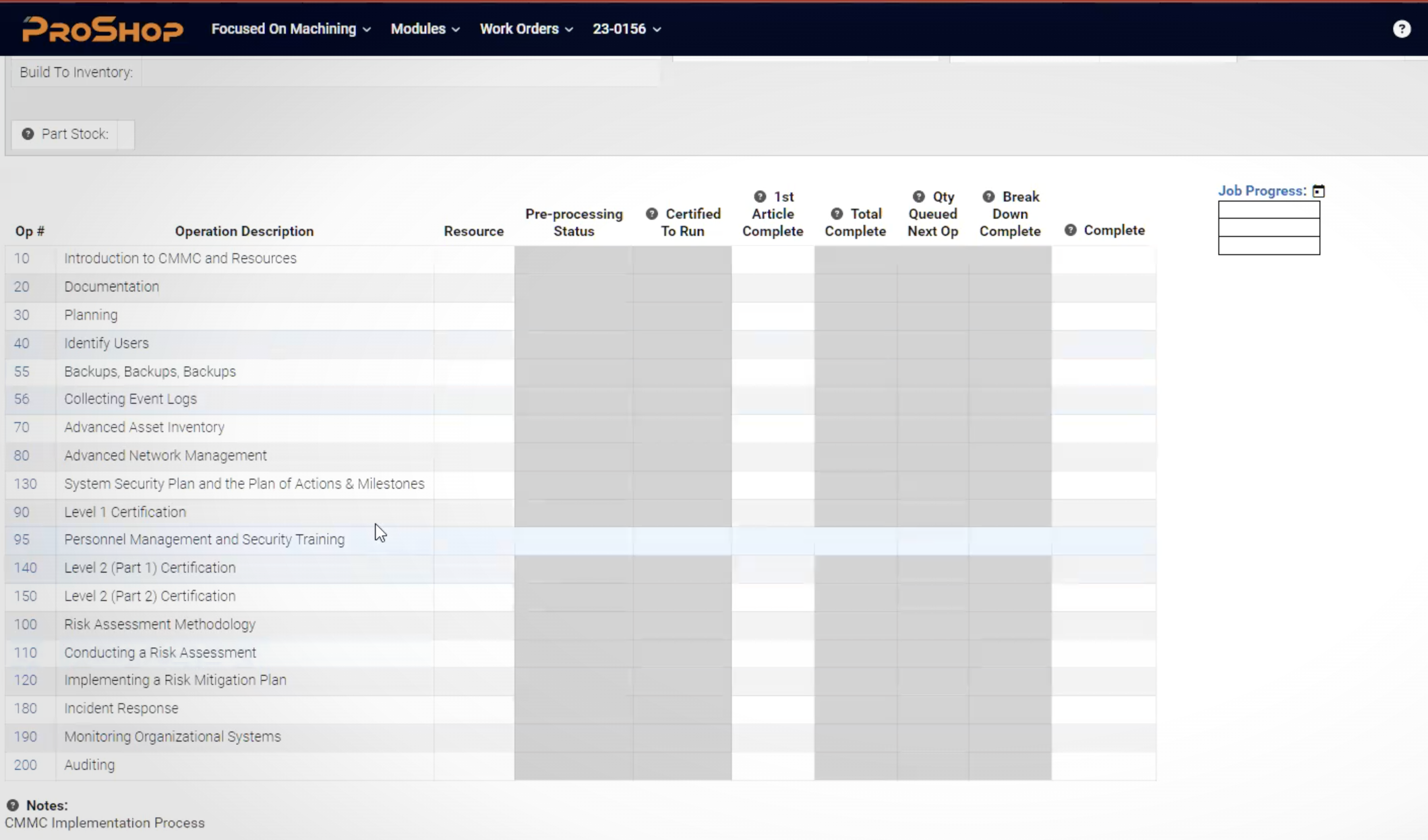

A Game-Changing Approach to Achieving CMMC 2.0 Compliance

Any manufacturer pursuing CMMC 2.0 compliance will tell you that the process is rigorous, to say the least. Focused on Machining is currently working to achieve Level 2 certification, which has a long list of 110 requirements aligned to NIST SP 800-171. We anticipate that our journey to CMMC certification will take us a total of 18 months when all is said and done.