BLOG

On-Time Delivery Starts Early: Protecting Your Timelines With Scheduling Visibility

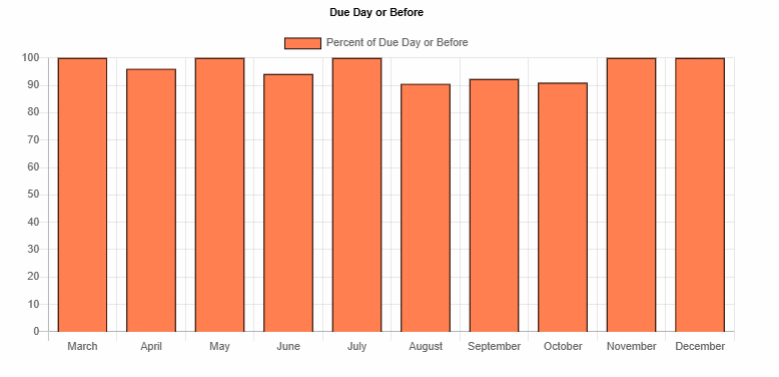

Some principles are just as important in both everyday life and manufacturing. One we’ve always followed at Focused on Machining is simple: don’t delay hard conversations. We’re proud of our 95% on-time delivery rate in our Colorado machine shop, but even in our shop, there are projects that might fall slightly behind plan. Waiting tends to only make outcomes worse, especially when lead times and schedules are on the line.

If a project might be delayed, we have built our shop to have the visibility to know that weeks or even months in advance. We always reach out early, explain what we’re seeing, and work with you to decide the best path forward.

On-Time Delivery Is a Priority at FOM

On-time delivery is central to how we plan and manage our work every single day. As an AS9100 machine shop, our baseline internal target is 90% on-time delivery. However, we never settle for that goal; we consistently exceed that benchmark, and in many months are able to achieve 100%.

Still, manufacturing is complex, and the unexpected happens all the time. Processes shift, materials arrive late, or parts slip at an outside vendor. But helping you see the risk early can make the difference between costly delays and smooth adjustments.

In fact, one thing we’ve heard many times from prime contractors is that they’re surprised how far in advance we can identify a risk. For example, in a recent conversation with ULA, we reviewed parts that were due in four months. Based on our schedule visibility, we told them there was a risk of a slight delay. But they said the advance notice allowed them to evaluate their options and avoid any sort of last-minute scramble. It’s one part of our shop’s commitment to customer service.

Advanced Tech and Granular Planning Create Visibility

That level of visibility comes from planning our projects to an extremely granular level of detail. In ProShop ERP, we create schedules that account for every stage of our work, from planning and machining through inspection, outside processing, and shipping. For instance, we don’t just lump together every step of shipping into a vague task marked “ship”; instead, we schedule specific steps like reviewing shipping paperwork and wrapping parts for shipment.

At first, that level of detail can seem excessive to some people, but it’s truly critical to staying on track and keeping lead times accurate. For a high-volume job, final packaging and prep can take a full day. If you compress everything into a generic two-hour task, you’re setting yourself up for delays before the job even begins.

What We Do When a Schedule Is at Risk

If a task falls behind its planned date in ProShop, the system alerts us and highlights the projected impact on the final due date. We’ve always built in buffers due to the amount of uncertainty that is natural in manufacturing. But if we see that buffer disappearing, we know it's time to act.

Early visibility allows us to respond with intention. First, we confirm whether the schedule slip is minor enough for us to catch up on, or if it may affect delivery. If we think the risk is real, we alert you immediately to the possibility of late arrival. Then, we review available options together.

If the delay stems from our actions, we always own that and are prepared to implement internal expedites without changing the price. But if a vendor or outside process is the bottleneck, we’ll talk through expediting options and weigh the tradeoff between added cost and delivery. We always want to make sure you can make an informed choice about the best outcome for your project.

Choose a Proactive Manufacturing Partner

These situations are rare, but they do happen. And when they do, transparency is non-negotiable at Focused on Machining.

Trust is built through consistent performance and honest communication. As a machine shop that prides itself on on-time delivery, we treat your deadlines as our own, and back that up with planning and accountability.

If you need a precision machining partner for your next project, request a quote today!