BLOG

Unlocking New Possibilities with 5-Axis Machining Technology

At Focused on Machining, we’re committed to serving the needs of our customers, and that means we’re continually investing in new technology. In our projects as an aerospace machine shop, in particular, today’s parts often include more challenging features than ever before. To meet those requirements, we’ve expanded our capabilities into 5-axis machining with a major new addition to our shop.

We are the proud new owners of a DVF 5000 with an eight-pallet auto work changer and 120-tool capacity. This full five-axis machine not only handles complex parts with speed and accuracy, it also enables more lights-out production, making us an even stronger manufacturing partner to our customers.

The Features That Define 5-Axis Parts

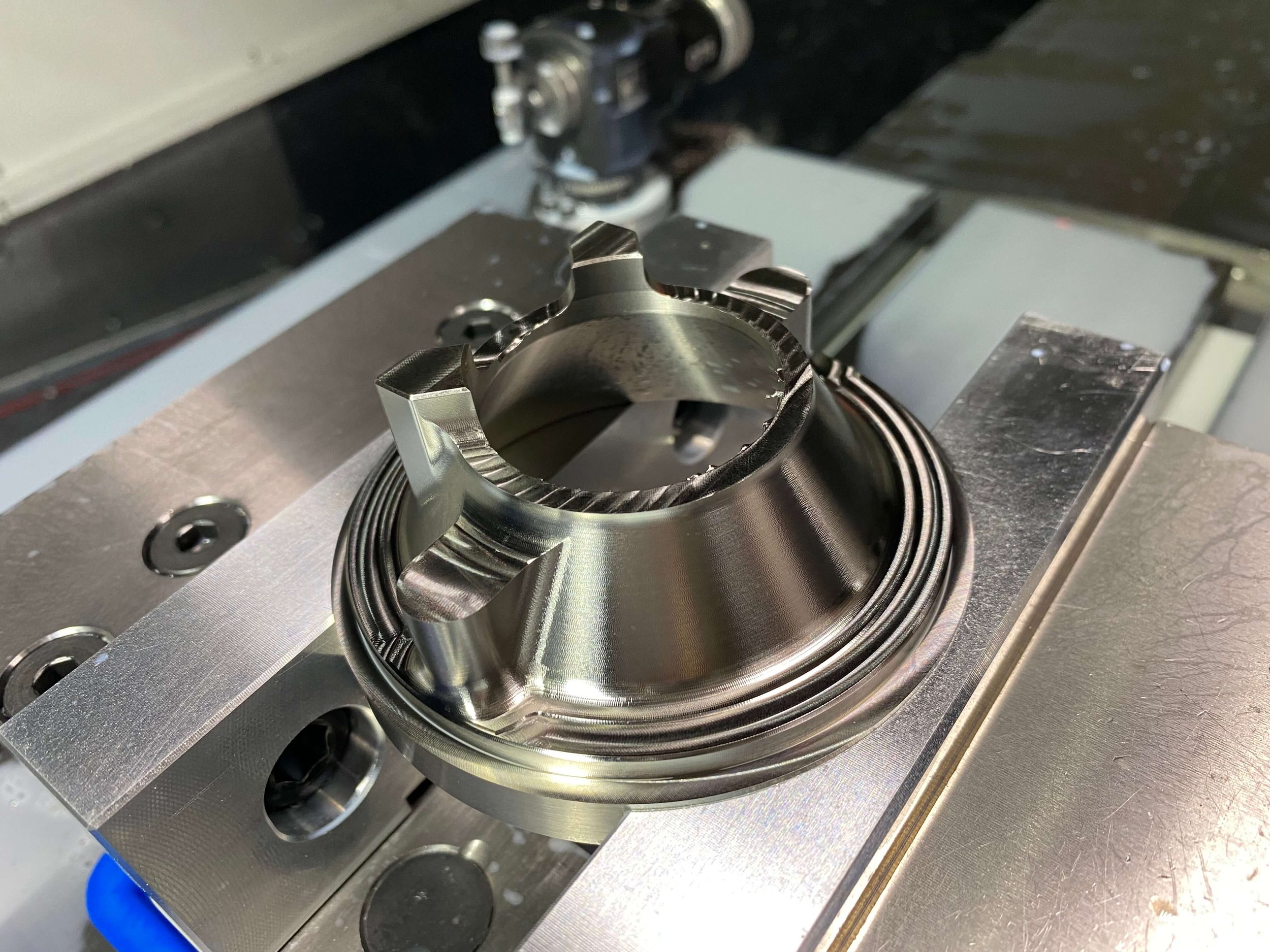

Our new machine is a full simultaneous 5-axis machining center, not a three-plus-two configuration. It can move the tool and workpiece along five different axes simultaneously. That allows us to tackle challenging features in fewer setups and with greater accuracy.

Some of the features that are simplified by our new machine include:

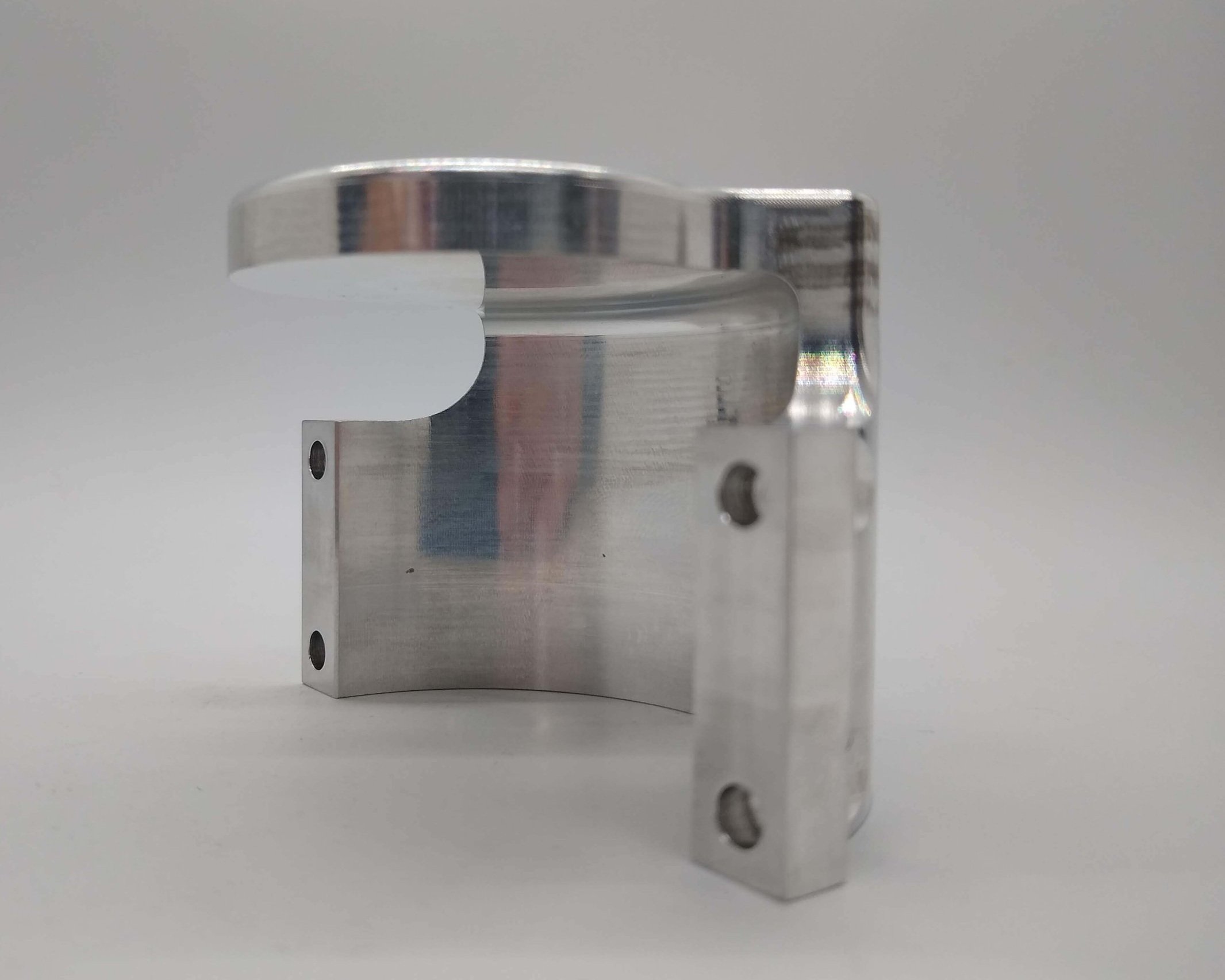

Complex Angles: Complex angles are a staple of 5-axis machining. For instance, consider a manifold with offset holes at different angles. This would require extensive fixturing in a vertical machine, adding to cost and lead time. With a 5-axis, we simply rotate to the correct angle and machine it.

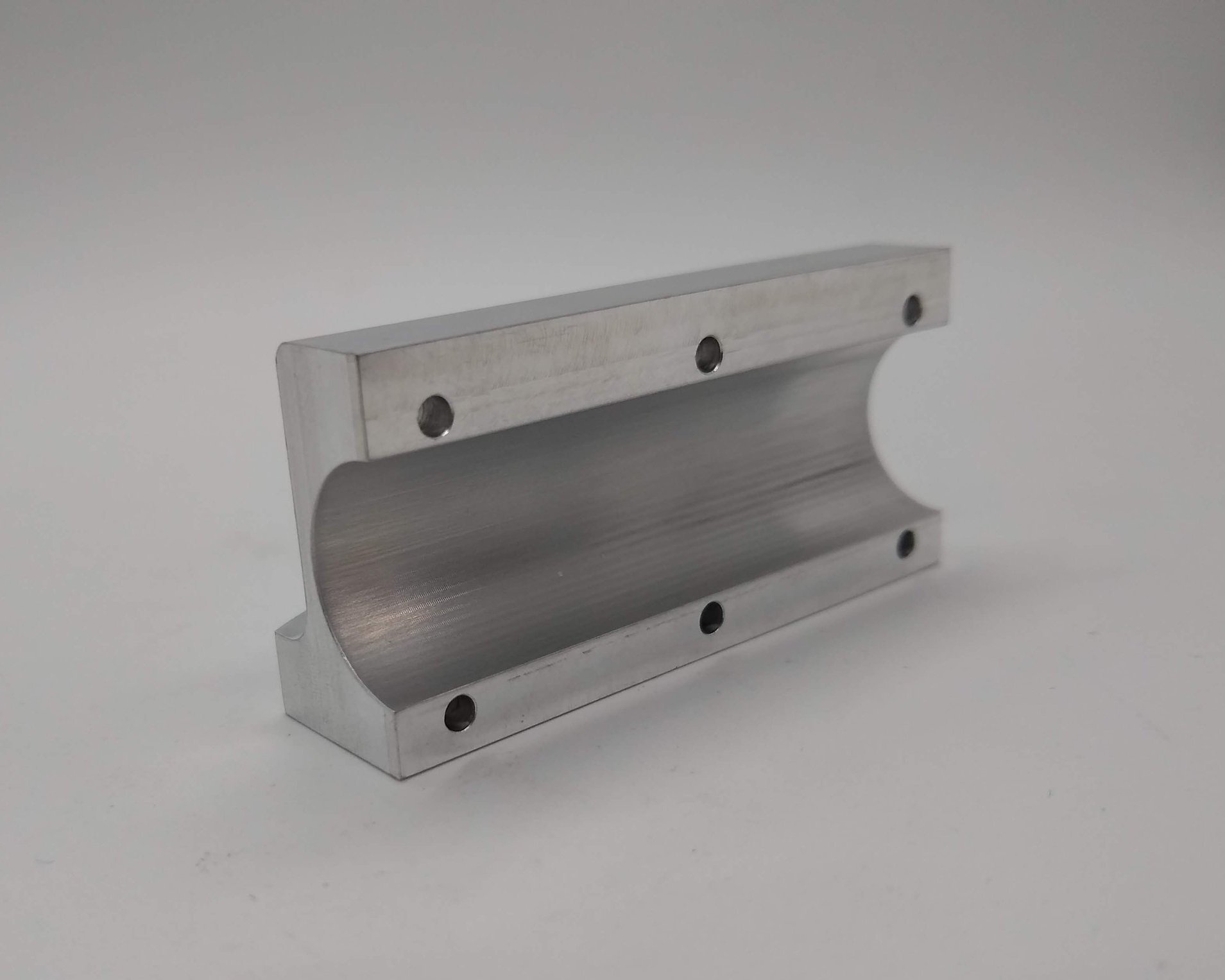

3D Surfaces: Curved or contoured surfaces can be completed in far fewer setups with a 5-axis machine. In fact, because our machine moves in all 5 axes at the same time, we can machine some 3D surfaces for customers that weren't possible before.

For instance, many aerospace parts must fit the skin of a rocket. A panel that bolts to a rocket with a 6-foot diameter would require customized setups and several operations in many machines, but can now be completed in only one or two.

A Closer Look at the Benefits to Our Customers

Beyond complex features, the new machine translates directly into several other benefits for our customers:

Faster production and shorter lead times: With a 20,000 RPM spindle, the DVF 5000 allows us to remove material at higher speeds without sacrificing accuracy. That means faster manufacturing so you get your delivery sooner.

Simultaneous machining: With 120 tools loaded, we can set up the machine to run a range of operations in the same cycle. The machine can switch between tools seamlessly even as it runs families of parts.

Greater lights-out capabilities: Even for complex jobs that require more than a dozen tools, we still have capacity in the tool magazine. Combined with our eight-pallet changer, the machine can be run 24/7 without interruption.

Efficient surface finishing: The high-speed spindle also results in smoother surface finishes. While we’ve always been known for delivering parts with quality surface finishes, this simplifies the process.

Enhancing Our Lights-Out Machining

While this five-axis machine is new to our shop, lights-out production is not. This new addition simply allows us to expand the types of parts we can run in a lights-out environment. Even parts with complex features requiring tight-tolerance machining can be produced lights-out, increasing our capacity without adding labor costs.

As part of our contract manufacturing services, we frequently machine multiple parts that integrate into a customer’s assembly. In the past, we may have delivered individual components piece by piece over months. Now, we can produce and ship all parts of the assembly at the same time. That allows your production team to begin the final assembly process earlier and improve your production timeline.

See What Our 5-Axis Machining Can Do

If you have a complex design, we’re ready to help. Our new investment means that even the most challenging parts are achievable, often with our efficient lights-out production.

Request a quote today and we’re confident we’ll soon become your go-to 5-axis machine shop!

Efficient Tight-Tolerance Machining With Our New In-Machine Probing

At Focused on Machining, we’re always looking for proactive investments in technology, both big and small, that allow us to be a better manufacturing partner to our customers. One recent upgrade was the integration of CIMCO probing technology, which has had a significant impact on our tight-tolerance machining.

At Focused on Machining, we’re always looking for proactive investments in technology, both big and small, that allow us to be a better manufacturing partner to our customers. One recent upgrade was the integration of CIMCO probing technology, which has had a significant impact on our tight-tolerance machining.

In-machine probing may not be a part of the manufacturing process most customers think about, but improving our programming and automation capabilities has us performing more efficiently. Some projects that previously required active supervision are now even moving into lights-out production. Learn the basics of this technology and why it leads to better pricing and faster delivery for you.

What Is CIMCO Probing?

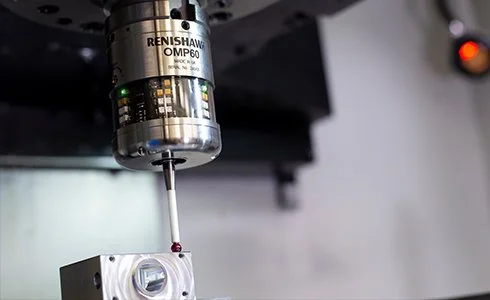

CIMCO probing is a Mastercam plugin that, essentially, allows us to include in-machine routines directly in our programming. We’ve made sure that every machine we’ve purchased in recent years is equipped with tool and spindle probes, but the actual probing process still had to be conducted manually by a machinist through the machine’s interface.

With CIMCO, probing is now fully automated. During programming, we define the exact features and dimensions the machine should check with the probe. Once machining begins, the probe automatically takes measurements and updates offsets before continuing to machine, all without any human intervention.

How It Improves Our Process

This technology has changed our setup and in-process inspection in two major ways, both of which have significantly reduced production time. First, it enables faster and more precise setups. Instead of requiring stock to be placed perfectly in a machine, the probe can now detect the stock’s position and adjust the program.

Second, as we machined parts in the past, we often had to bring them to quality inspection mid-process. If an issue was found, we may have to restart the part entirely. Now, with CIMCO, the machine can automatically detect and correct small discrepancies.

How CIMCO Benefits Our Customers

Faster machining: This upgrade has drastically reduced the time required for precision machining through its improvements to manual setup and back-and-forth with the quality department. For some jobs, setup time alone can be reduced by several hours.

Better pricing: When parts require less operator activity, labor costs will decrease as a consequence. Those savings are passed onto customers, making tight-tolerance machining more economical.

Expanded lights-out capabilities: Some parts that previously required consistent supervision can now be produced unattended, increasing our shop’s capacity and speeding up delivery, a key advantage for customers who leverage our contract manufacturing services.

Real-World Example: Enabling Lights-Out for a Military Component

We recently employed CIMCO probing on a large, complex aluminum part for a defense partner. The part measured 25” x 22” x 6” and included multiple machined pockets with threaded holes and true position callouts.

In the past, we simply could not have manufactured this part lights-out. The setup for the massive piece of aluminum stock was too demanding, and the threading required manual supervision to ensure accuracy. Now, we use the probe to check the pocket dimensions after machining and then use its XY coordinates as offsets to add related features, a process that previously had to be done manually.

As a result, the part is now a straightforward lights-out job, with faster delivery and the same precision.

Let’s Revisit Your Toughest Parts

Have you ever sent us a part for tight-tolerance machining that wasn’t a good match for our lights-out capabilities? Let’s discuss that project again, because it may be well-suited to automated production with our new CIMCO capabilities. And with less operator supervision, you could see more cost-effective pricing.

Request a quote now or contact us today to see how the upgrades at our Colorado CNC machine shop can simplify your next part!

Industry Spotlight: Partner With a Veteran-Led Aerospace and Defense Machine Shop

At Focused on Machining, we’re proud of our work as an aerospace and defense machine shop because it’s personal for us. Our owner, Justin Quinn, spent six years in the United States Air Force, serving around the world as a C-17 aircraft mechanic. Now, Justin is passionate about supporting the men and women behind every mission in his work leading a CNC machine shop.

At Focused on Machining, we’re proud of our work as an aerospace and defense machine shop because it’s personal for us.

Our owner, Justin Quinn, spent six years in the United States Air Force, serving around the world as a C-17 aircraft mechanic. Now, Justin is passionate about supporting the men and women behind every mission in his work leading a CNC machine shop.

We support the aerospace and defense sectors with high-quality, tight-tolerance machining backed by critical certifications, extensive documentation, and a veteran’s commitment to excellence.

Precision and Documentation: The Foundation of Aerospace Machining

In aerospace and defense, precision isn’t optional—it’s critical. Faulty parts can compromise an entire mission, and that’s why customers in these industries not only have extremely high standards, they demand clear documentation to ensure quality and compliance at every stage.

Our shop leverages ProShop ERP to ensure complete transparency and traceability throughout every aspect of manufacturing. From material certifications to calibration logs to inspection reports, every detail is tracked. When customers need documentation, we’re ready.

Certifications to Meet All Your Requirements

For an aerospace and defense machine shop, certain credentials are non-negotiable. We maintain some of the most important certifications for these sectors:

AS9100 and ISO 9001:2015 Certifications: AS9100 includes all ISO 9001:2015 requirements, along with additional standards for aerospace and defense. Together they demonstrate our commitment to excellence in quality systems for both general and industry-specific projects.

ITAR Registered: We are fully staffed by U.S. citizens and authorized for sensitive defense work.

CMMC Level 2 Compliant: We are ahead of the curve on cybersecurity and will be CMMC Level 2 compliant in the coming months.

Service-Disabled Veteran-Owned Small Business: We’re proud of our veteran-owned status and can provide our customers with official documentation when needed.

Advanced Machining Capabilities for Precision Parts

Our aerospace and defense machine shop is built specifically to address the challenges of manufacturing for customers in these demanding industries, with capabilities including:

Multi-Axis Machining With Deep Aluminum Expertise

Our advanced multi-axis equipment machines parts with complex geometries in fewer setups, reducing lead times while increasing accuracy and repeatability for custom CNC machining projects. And while our shop works with a variety of materials, our experience with common aerospace options such as 6000 and 7000 series aluminum allows us to machine parts quickly without compromising accuracy.

Assembly Services

We streamline your workflows by delivering completed subassemblies, including performing high-volume rivet installation and installing hardware like nut plates that can be essential to aerospace projects.

Tight Tolerance Machining

Other shops might no-quote jobs with tolerances under +/- 0.0005”, but we’re always ready to meet your specifications. Our skilled machinists and advanced inspection equipment ensure precise results every time.

Streamline Your Projects With Focused on Machining

When we talk to engineers and buyers for aerospace and defense organizations, they often tell us they’re juggling a variety of different vendors: one for tight tolerance machining, one for certain certifications, one for specialized capabilities, and more. At Focused on Machining, we offer all of these in a single precision machine shop, backed by a team that truly understands your mission.

Request a quote to partner with a veteran-led shop with expertise in the aerospace and defense industries!

Material Spotlight: 7000 Series Aluminum

At Focused on Machining, we bring years of expertise across a wide range of materials such as stainless steel, titanium, Monel and Inconel. Here, we’re focusing on our experience with 7000 series aluminum, a strong alloy that’s a popular material choice in a variety of industries.

At Focused on Machining, we bring years of expertise across a wide range of materials such as stainless steel, titanium, Monel and Inconel. Here, we’re focusing on our experience with 7000 series aluminum, a strong alloy that’s a popular material choice in a variety of industries.

An Overview of Aluminum 7000 Series

The 7000 series of aluminum alloys is among the strongest aluminum alloys available. It’s well known for its applications in aerospace and structural components. Because of our extensive experience in aerospace machining, we’ve grown very familiar with 7000 series aluminum.

7000 series aluminum has zinc as its primary alloying element, which differentiates it from 6000 series aluminum, another popular aluminum alloy that we often machine. The zinc content gives it high tensile strength properties, and its strength-to-weight ratio is one reason it’s so popular in applications like aircraft.

At Focused on Machining, we frequently work with several popular alloys from the 7000 series, with 7075 aluminum being the most common. This alloy is prized for its impressive strength-to-weight ratio, machinability, and the ability to further enhance its strength through heat treatment. We also regularly machine 7050 aluminum, another high-performance alloy in the 7000 series.

Among the drawbacks of 7075 is its limited corrosion resistance, which leads some engineers to choose 6000 series aluminum instead.

7000 Series Aluminum at Focused on Machining

We have been machining 7075 and 7050 for many years at our Colorado CNC machine shop, we sometimes feel like we’ve done it all with these alloys. Our customers see several benefits from our deep experience with 7000 series aluminum:

Speed: When a machine shop lacks experience with alloys like 7050, they often move cautiously, double-checking tooling and slowing down production. At Focused on Machining, we’re so confident in our expertise with 7075 and 7050 aluminum that we push our machines to their limits every time. This ensures that our customers receive their parts as quickly as possible without compromising on quality.

Price: We order so much of these materials that it’s unlikely any other shop can beat our pricing. We’re always getting the best prices from vendors because we have a long-term relationship with them and we’re ordering in such large quantities.

Processing: 7000 series aluminum often requires multiple post-processing steps and inspections. We have a trusted network of reliable aluminum processors who are experienced in working with these alloys. They are able to handle all of these processes under one roof, reducing lead time and minimizing the chances of any damage in shipping.

Knowledge: At certain times, there may be limited availability for a particular variety of 7000 series. For instance, maybe a customer asks for a large bracket in 7075 T6 six-inch plate, and we are not able to find it at that moment. However, we have the suppliers and the machining experience to find and machine it from T3 six inch plate or 7050 T6 six inch plate.

Talk to Us About Your Next 7000 Series Aluminum Project

At Focused on Machining, we’ve been making high-quality parts from 7000 series aluminum for years. We have the expertise to make what you need and the trusted partner network to get any post-processing steps done. And if you’re not sure if 7000 series aluminum is right for your project, we can offer some advice on selecting the right material for your CNC machined part.

Request a quote today to see how we can help with your next project.

How Customers Benefit from Our Lights-Out Manufacturing Capabilities

Focused on Machining offers lights-out machining as part of our CNC production machining services. These capabilities allow us to run orders around the clock so we can provide faster lead times, lower costs, and better flexibility.

Focused on Machining offers lights-out machining as part of our CNC production machining services. These capabilities allow us to run orders around the clock so we can provide faster lead times, lower costs, and better flexibility.

We currently have significant capacity on our DN Solutions NHP 4000, a horizontal lights-out machining center equipped with a 275-tool matrix and 12-station linear pallet system. Keep reading to find out how this machine benefits customers and if your part is a good candidate for it.

Benefits of Our Horizontal Lights-Out Machining Center

The NHP 4000 is essentially a horizontal machining center attached to a 12-pallet system. There are 12 tombstones in the pallet pool, and each tombstone has four sides, giving us 48 machining tables in just one machine. Once loaded and programmed, the NHP 4000 will run unattended until it runs out of work.

Here are the top three benefits customers can expect:

1. Cost-effectiveness

Labor factors significantly into the cost of machined parts. Generally, the more labor required, the higher the price. Because the NHP 4000 is highly automated, labor is only necessary during the initial programming and setup and when it’s time to change out a part and add raw stock. This benefit lets us keep our internal costs low and pass savings on to customers.

Ultimately, you get work done on one of the most advanced and expensive machines in our CNC production machining services department for a highly competitive rate.

2. Just-in-time inventory

The NHP 4000 is ideal for long-term contracts involving repeat parts machined and delivered at planned intervals over a fixed period of time. Once the parts have been programmed, we can run them with the click of a button, allowing us to machine them as close to the delivery date as possible without having to hold inventory on our shelves.

Have a revision change? Just let us know, and we’ll update the programming before your next delivery.

3. Flexibility

The ability to run parts with the click of a button gives us the flexibility to accommodate schedule changes and last-minute requests for repeat parts.

Need a short run of parts we’ve already programmed? We can get you what you need right away without charging you expedite fees.

Is Your Part Right for Our Horizontal Lights-Out Machining Center?

The NHP 4000 allows us to quote highly competitive prices for complex parts, but there are some caveats. Generally, parts should check these boxes:

High-volume or repeat. The initial programming and setup costs must be spread across a high enough volume of parts for the cost per part to be competitive. A good way to think of it is the longer the repeatability period, the higher the volume. For instance, if you only need one order annually, the volume should be in the hundreds; if you need monthly orders over an annual period, as few as five parts per month is tenable.

Moderately complex. Regarding part complexity, the sweet spot for this machine is a moderately complex part with numerous features and/or features on all sides that do not require 5-axis machining services.

Aluminum. Because aluminum is easy to cut and causes minimal tool wear, running aluminum parts unattended is relatively low risk. A harder material like stainless steel presents more opportunities for error.

If your part doesn’t check all these boxes, it’s still worth having a conversation to determine whether the NHP 4000 could be the right fit. As of June 2024, we have 8,000 hours of open machining capacity for it that we are eager to fill with your parts!

7 Reasons to Work with Our AS9100 Machine Shop

Remember when we shared that we were in the process of getting AS9100 certified? Well, we’re thrilled to announce that Focused on Machining is now officially an AS9100 machine shop!

Top Shops data indicates that only 45% of machine shops have quality certifications like ISO 9001 and AS9100, and we’re proud that our Denver machine shop is part of this elite group.

Remember when we shared that we were in the process of getting AS9100 certified? Well, we’re thrilled to announce that Focused on Machining is now officially an AS9100 machine shop!

Top Shops data indicates that only 45% of machine shops have quality certifications like ISO 9001 and AS9100, and we’re proud that our Denver machine shop is part of this elite group.

Being AS9100 certified means that we follow a strict set of quality management system requirements to ensure that we provide safe and reliable parts to aerospace customers.

We already have loads of experience machining aerospace prototypes. But this certification will allow us to deepen our relationships and work with customers on low-volume production runs as well.

How Customers Benefit from Working with Our AS9100 Machine Shop

Customers across all industries benefit from working with an AS9100 machine shop. In preparation for this certification, we’ve honed our processes and operations to provide better service than ever. Here’s what you can expect from Focused on Machining:

Comprehensive documentation. Formal inspection reports are an industry standard for aerospace. But no matter what industry you’re in, your parts will benefit from going through our full quality process. Rather than limiting this process to only the customers who require inspection data, we conduct inspections and formally document the results for each part we machine. We also generate first article inspection (FAI) reports as part of this process.

Formal PO confirmations. When we confirm a date and price to a customer, we’re dead set on delivering on those promises no matter what. Before confirming a PO, we conduct due diligence to verify things like material pricing and availability and overall project timeline. Our goal is to always negotiate upfront with customers instead of flying by the seat of our pants and having to negotiate on the back end.

Part tracking. With the click of a button, our comprehensive ERP system tells us exactly where a part is in the manufacturing process—whether it’s in machining, inspection, outside processing, or ready to ship. We can provide full visibility into anything from the amount of time spent on the part to the machine it’s currently on. All you have to do is ask.

Detailed box labels. We take pride in our box labels, which include a clear image of the part and key details like revision number, work order number, quantity, and more. Many customers have told us that these box labels help streamline their own receiving processes. One customer even uses our packaging as part of their inventory system because it has all the information they need.

No paper trails. We store all data digitally in our secure ERP system. You never have to worry about your proprietary information floating around our shop.

Serialization. An increasing number of customers have been asking us to serialize their parts and we’re more than happy to deliver. Our machinists track and number each part sequentially and can even laser engrave part numbers at your request.

Faster turnaround. As a result of our streamlined processes, we’re working more efficiently than ever before. Although material shortages are slowing down everyone in manufacturing right now, we remain committed as ever to our promise of high-quality CNC machined parts when YOU need them.

For us, the best thing about being an AS9100 machine shop is that it gives us the opportunity to take on more of the aerospace machining projects we love most—from complex titanium parts to internal and external components for Nitronic 60 minisatellites.

Here’s a look at some of the aerospace parts we’ve made recently:

Focused on Machining is ready and excited to put our aerospace machining expertise to the test for you. If you’re looking for a reliable AS9100 machine shop, we hope you’ll trust us with your part.