Efficient Tight-Tolerance Machining With Our New In-Machine Probing

At Focused on Machining, we’re always looking for proactive investments in technology, both big and small, that allow us to be a better manufacturing partner to our customers. One recent upgrade was the integration of CIMCO probing technology, which has had a significant impact on our tight-tolerance machining.

In-machine probing may not be a part of the manufacturing process most customers think about, but improving our programming and automation capabilities has us performing more efficiently. Some projects that previously required active supervision are now even moving into lights-out production. Learn the basics of this technology and why it leads to better pricing and faster delivery for you.

What Is CIMCO Probing?

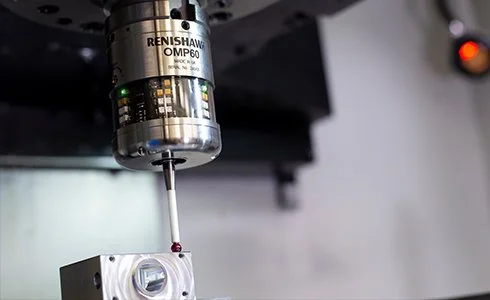

CIMCO probing is a Mastercam plugin that, essentially, allows us to include in-machine routines directly in our programming. We’ve made sure that every machine we’ve purchased in recent years is equipped with tool and spindle probes, but the actual probing process still had to be conducted manually by a machinist through the machine’s interface.

With CIMCO, probing is now fully automated. During programming, we define the exact features and dimensions the machine should check with the probe. Once machining begins, the probe automatically takes measurements and updates offsets before continuing to machine, all without any human intervention.

How It Improves Our Process

This technology has changed our setup and in-process inspection in two major ways, both of which have significantly reduced production time. First, it enables faster and more precise setups. Instead of requiring stock to be placed perfectly in a machine, the probe can now detect the stock’s position and adjust the program.

Second, as we machined parts in the past, we often had to bring them to quality inspection mid-process. If an issue was found, we may have to restart the part entirely. Now, with CIMCO, the machine can automatically detect and correct small discrepancies.

How CIMCO Benefits Our Customers

Faster machining: This upgrade has drastically reduced the time required for precision machining through its improvements to manual setup and back-and-forth with the quality department. For some jobs, setup time alone can be reduced by several hours.

Better pricing: When parts require less operator activity, labor costs will decrease as a consequence. Those savings are passed onto customers, making tight-tolerance machining more economical.

Expanded lights-out capabilities: Some parts that previously required consistent supervision can now be produced unattended, increasing our shop’s capacity and speeding up delivery, a key advantage for customers who leverage our contract manufacturing services.

Real-World Example: Enabling Lights-Out for a Military Component

We recently employed CIMCO probing on a large, complex aluminum part for a defense partner. The part measured 25” x 22” x 6” and included multiple machined pockets with threaded holes and true position callouts.

In the past, we simply could not have manufactured this part lights-out. The setup for the massive piece of aluminum stock was too demanding, and the threading required manual supervision to ensure accuracy. Now, we use the probe to check the pocket dimensions after machining and then use its XY coordinates as offsets to add related features, a process that previously had to be done manually.

As a result, the part is now a straightforward lights-out job, with faster delivery and the same precision.

Let’s Revisit Your Toughest Parts

Have you ever sent us a part for tight-tolerance machining that wasn’t a good match for our lights-out capabilities? Let’s discuss that project again, because it may be well-suited to automated production with our new CIMCO capabilities. And with less operator supervision, you could see more cost-effective pricing.

Request a quote now or contact us today to see how the upgrades at our Colorado CNC machine shop can simplify your next part!