BLOG

How Our Aerospace and Medical Machine Shop Keeps Lead Times Short

Never one to shy away from an opportunity, our aerospace and medical machine shop is committed to being the small shop customers need in this challenging climate. Keep reading to learn how we’ve improved efficiency to meet even the tightest deadlines.

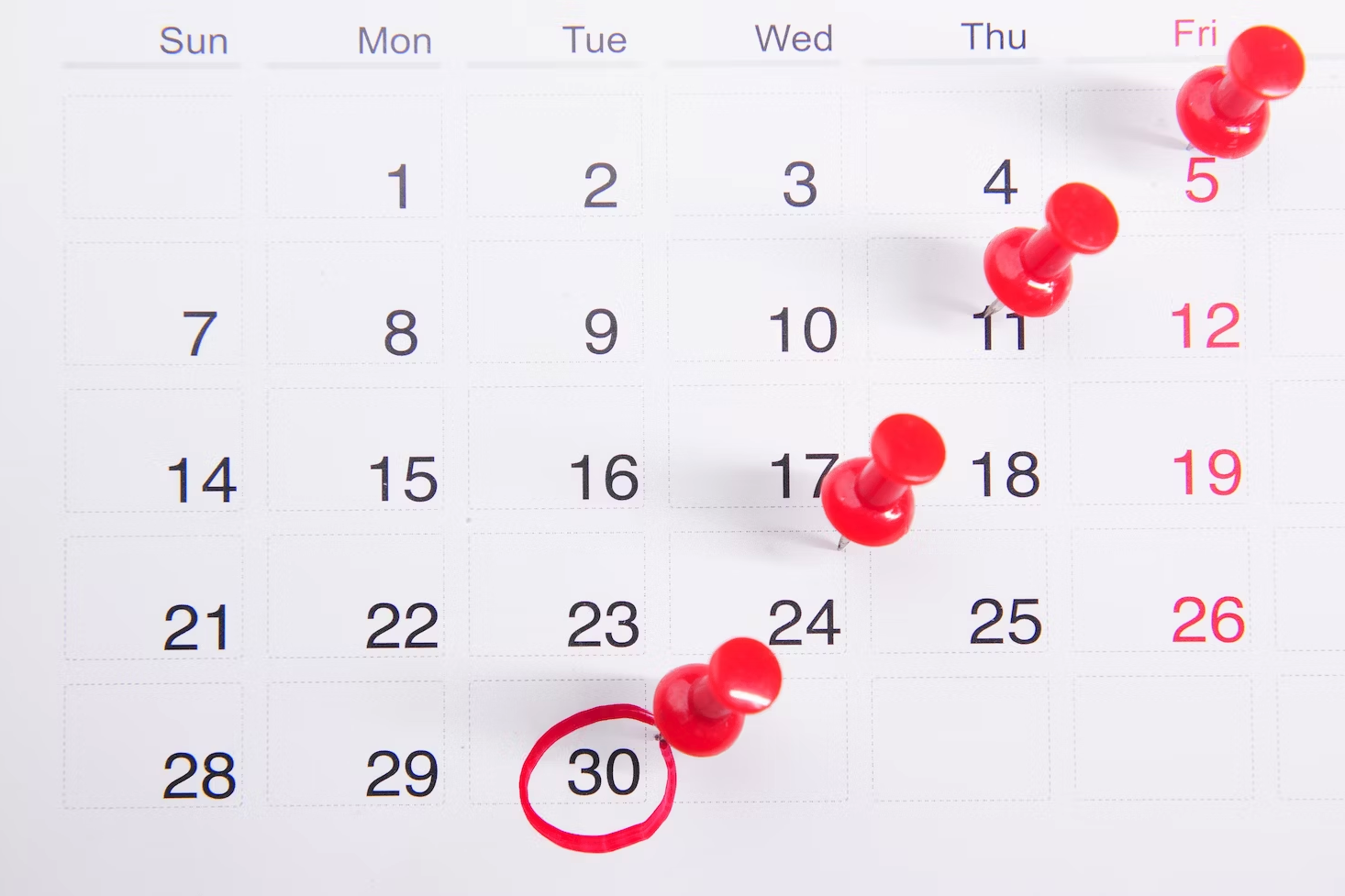

Manufacturing lead times are getting longer, and this trend will likely continue as more small shops close down or are bought by bigger shops. On the flip side, today’s customers expect lead times to be shorter than ever—three weeks or less in our recent experience.

Never one to shy away from an opportunity, our aerospace and medical machine shop is committed to being the small shop customers need in this challenging climate. Keep reading to learn how we’ve improved efficiency to meet even the tightest deadlines.

Award-Winning Manufacturing Software Integration

When manual data entry was slowing us down, we knew it was time to integrate our quoting software and ERP system. So we collaborated with Paperless Parts and ProShop to develop a solution that would work not only for us but also for other shops.

Paperless Parts takes the data we initially enter, converts it accordingly, and sends it directly to ProShop for fast and accurate generation of estimates, parts, and purchase orders. ProShop then creates the purchasing requirements so we can quickly order materials and other necessary items.

It used to take us up to an entire business week to enter a PO and order materials. Now, when we receive a PO, we can have the material on order within 30 minutes. It’s not uncommon for us to receive the material at our aerospace and medical machine shop quicker than some shops enter an order into their system

Focused on Machining Wins NTMA and AMT’s Technology Excellence Award

We’re proud to say that our work helping to integrate Paperless Parts and ProShop won Focused on Machining NTMA and AMT’s Technology Excellence Award in 2023. The award recognizes member companies working to improve their businesses with advanced technology.

Eliminating Bottlenecks on the Shop Floor

We’re not only increasing efficiency at the front end of projects. We’ve also implemented measures to streamline operations on the shop floor.

Waiting on programming departments to program parts creates a bottleneck in many shops. To prevent this problem at our aerospace and medical machine shop, we’re training our machinists to become skilled programmers.

Now, when we’re in a rush situation, we can bypass the programming department entirely and have the machinist assigned to the part perform the programming.

We’re also brainstorming solutions for making our quality control process more efficient for tight tolerance parts, which tend to require time-intensive inspections.

Innovative Solutions to Real Industry Challenges

In an unpredictable industry, Focused on Machining strives to be a source of stability and reliability for our customers. We’re committed to continuously improving our internal processes to keep lead times short and customers happy.

Request a quote and let us know how we can support you.

Is Your Blueprint Setting You up for a Bad Assembly?

There’s no shortage of precision machine shops that will build a part to print without giving it a second thought. Don’t get us wrong; there’s something to be said for nailing all the specifications on a blueprint. But in many cases, simply adhering to a part’s specifications can lead to significant fit, form, and functionality problems. This is especially true when manufacturing parts destined for an assembly.

There’s no shortage of precision machine shops that will build a part to print without giving it a second thought. Don’t get us wrong; there’s something to be said for nailing all the specifications on a blueprint. But in many cases, simply adhering to a part’s specifications can lead to significant fit, form, and functionality problems. This is especially true when manufacturing parts destined for an assembly.

A Blueprint Doesn’t Always Tell the Complete Story

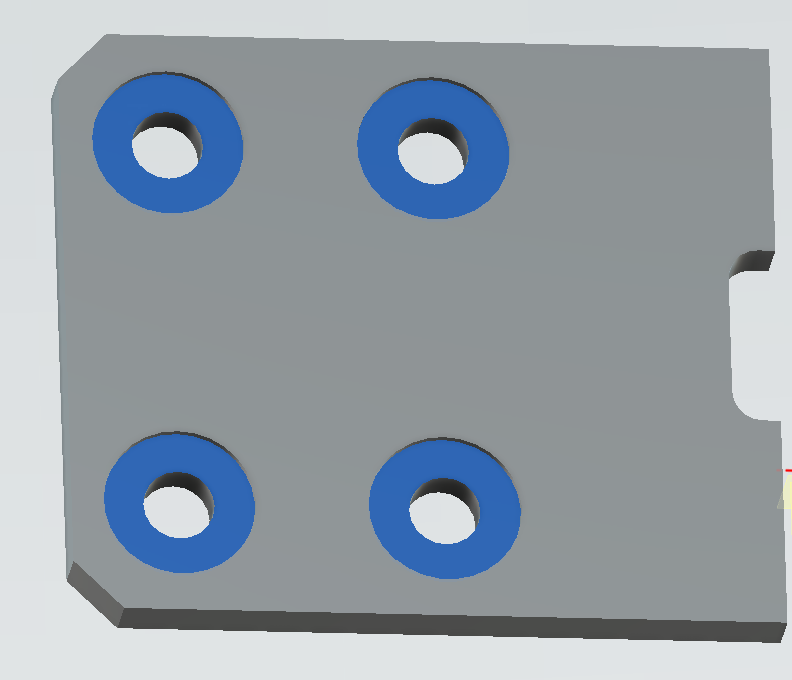

We’ve encountered numerous aerospace machining projects where a part’s blueprint doesn’t tell the complete story, though one recent assembly project comes to mind.

The customer contacted our AS9100 machine shop for a 3” diameter rotary shaft with a keyway cut and a separate ring that fits over the shaft and locks in via keystock. Their print indicated that we should purchase an off-the-shelf shaft with the keyway already cut into it; we would only need to perform some minor machining.

The problem was that the tolerances on the customer’s blueprint were tighter than those on the off-the-shelf shaft. If we were to follow their blueprint’s specifications, we would’ve had to make each of the units a perfect match fit consisting of a shaft, keystock, and ring that would only fit with each other. Not exactly ideal for a 70-unit assembly!

Upfront communication is critical in aerospace machining, so we contacted the customer immediately with our concerns and proposed an alternative solution. Instead of building the parts to print, we would build them with the bigger picture in mind.

We explained that in veering from the blueprint, we could guarantee that any of the rings fit with any of the shafts and lock in place with any of the keystocks. And we were right. We machined the parts and performed comprehensive test fits for verification before shipping the parts off to our happy customer.

When in Doubt, Talk to Your Aerospace Machining Partner

With that particular project, we could easily identify the problems presented by the blueprint because we were making all the parts for the assembly and knew what the customer expected from the final assembly. But that’s not always possible if, say, a customer sources an assembly’s parts from different shops. Or even if they source the parts from the same shop but fail to provide context on how the parts must fit together.

That’s why we like to tell customers: when designing an assembly, bring your aerospace machining partner into the conversation as early as possible. Tell them about your assembly and how the parts must interact with one another. Don’t wait for them to waste a few days trying to figure out a solution to a problem they’ve identified in your blueprint.

A good AS9100 machine shop can offer valuable advice to ensure your assembly fits and functions as intended. In many cases, our recommendations involve loosening tolerances depicted as unnecessarily tight on the blueprint. And because every decimal place adds a zero to the price, these recommendations can save you substantial money.

If possible, work with the same aerospace machining partner for all the parts in an assembly. When a shop has an opportunity to take a high-level, big-picture approach to your assembly project, you’ll ultimately benefit from a smoother process and better results. At Focused on Machining, we can even build your assembly and ship it to you ready to go.

If you have an assembly project on the horizon, we want to hear about it! Request a quote and tell us you’d like our support in finalizing the blueprint for your assembly.

Medical CNC Machining: Material Spotlight

Focused on Machining has built a reputation as a top aerospace machine shop. We love the work we do for aerospace and space customers. But we want anyone reading this to know that our expertise extends into another major focus area: medical CNC machining.

Focused on Machining has built a reputation as a top aerospace machine shop. We love the work we do for aerospace and space customers. But we want anyone reading this to know that our expertise extends into another major focus area: medical CNC machining.

Medical CNC Machining at Focused on Machining

While we don’t make parts that go inside the human body, we support the medical industry by machining parts for other critical applications, like testing equipment for artificial heart valves.

The capabilities and AS9100-compliant processes we’ve developed to serve aerospace customers directly benefit medical customers in key ways:

We guarantee material traceability throughout the manufacturing process

We specialize in machining tight tolerances and intricate features

We adhere to a rigorous inspection process for every part we machine

We regularly machine materials commonly used in medical applications

Common Medical CNC Machining Materials

Let’s closely examine three of the materials we encounter most frequently for medical CNC machining projects.

316 Stainless Steel

Sometimes called 316 surgical steel for its common use in medical applications, 316 stainless steel has excellent anti-corrosive properties due to its high nickel content. It’s ideal for medical parts that come into contact with liquid in their application or must be sterilized regularly. We can coordinate passivation services with a trusted vendor to further enhance corrosion resistance.

We also regularly send 316 stainless steel medical parts out for electropolishing services per customer request. Electropolishing smooths the part’s surface, reducing microscopic cracks and crevices to achieve close to a mirror-like finish. Smooth surfaces are critical for many medical applications because the smoother the surface, the fewer opportunities for bacteria to accumulate.

Aluminum

Budget-friendly aluminum can be a great alternative to 316 surgical steel for certain medical applications. It boasts excellent corrosion-resistant properties, enabling it to withstand frequent sterilization.

A significant benefit of aluminum is that it’s durable but notably lightweight compared to other metals and alloys. For this reason, it’s commonly found in products like trays and containers, hospital room equipment, and portable field equipment.

Acetal

This semi-crystalline thermoplastic rivals metals with its excellent strength, performance, and workability. As a slippery, low-friction material, it’s a great choice for parts with sliding mechanisms.

Acetal is relatively easy to machine, enabling medical machine shops to achieve tight tolerances and complex features accurately and efficiently. It’s also possible to achieve exceptionally smooth surface finishes with acetal.

The material has good chemical resistance properties and can be sterilized using various methods.

Make Focused on Machining Your Trusted Medical Machine Shop

If you’re looking for a reliable partner for medical CNC machining services, we hope you’ll consider Focused on Machining.

We have extensive experience machining 316 stainless steel, aluminum, acetal, and other materials used in medical applications. Let us put our expert team to work on your next project.

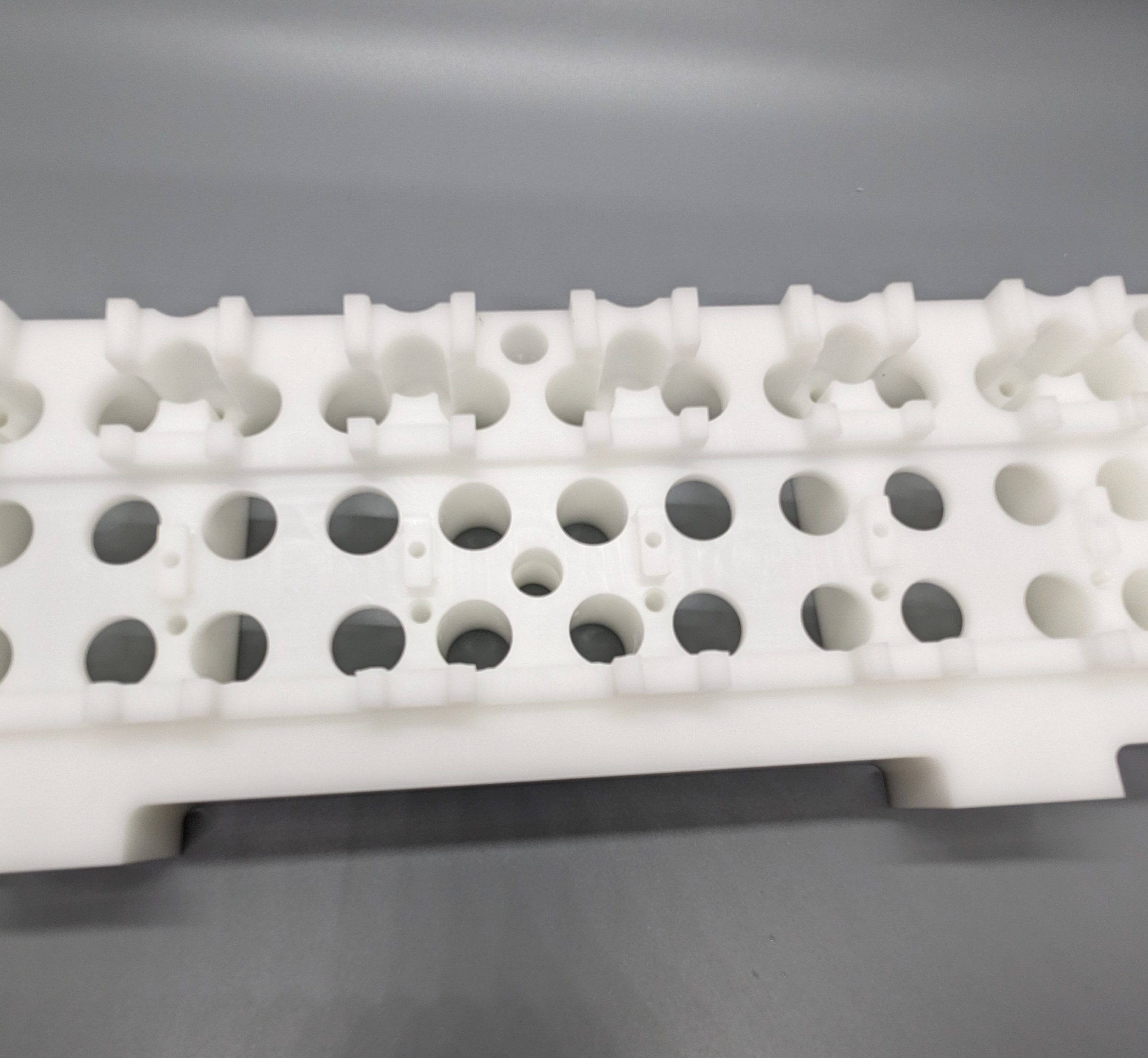

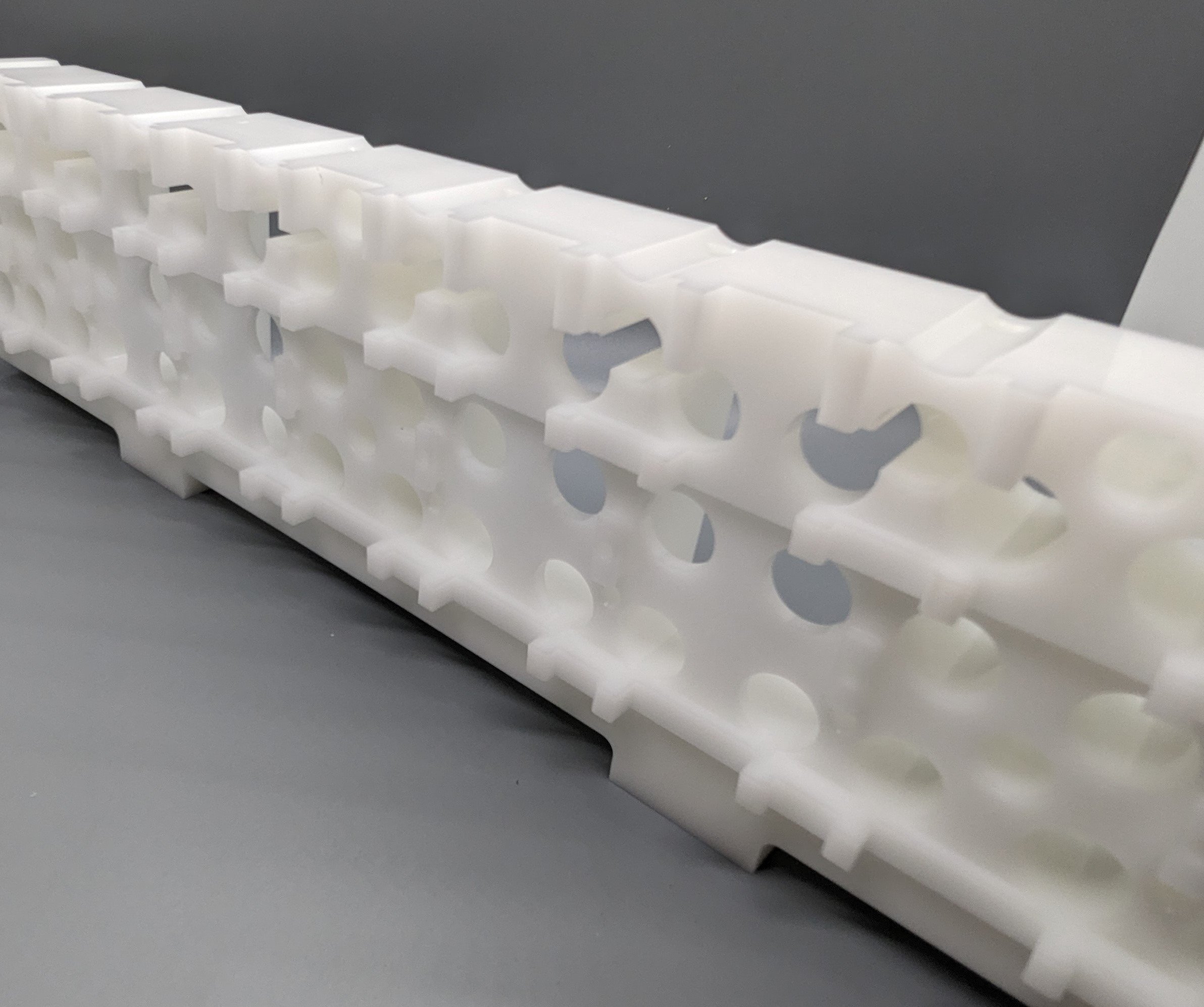

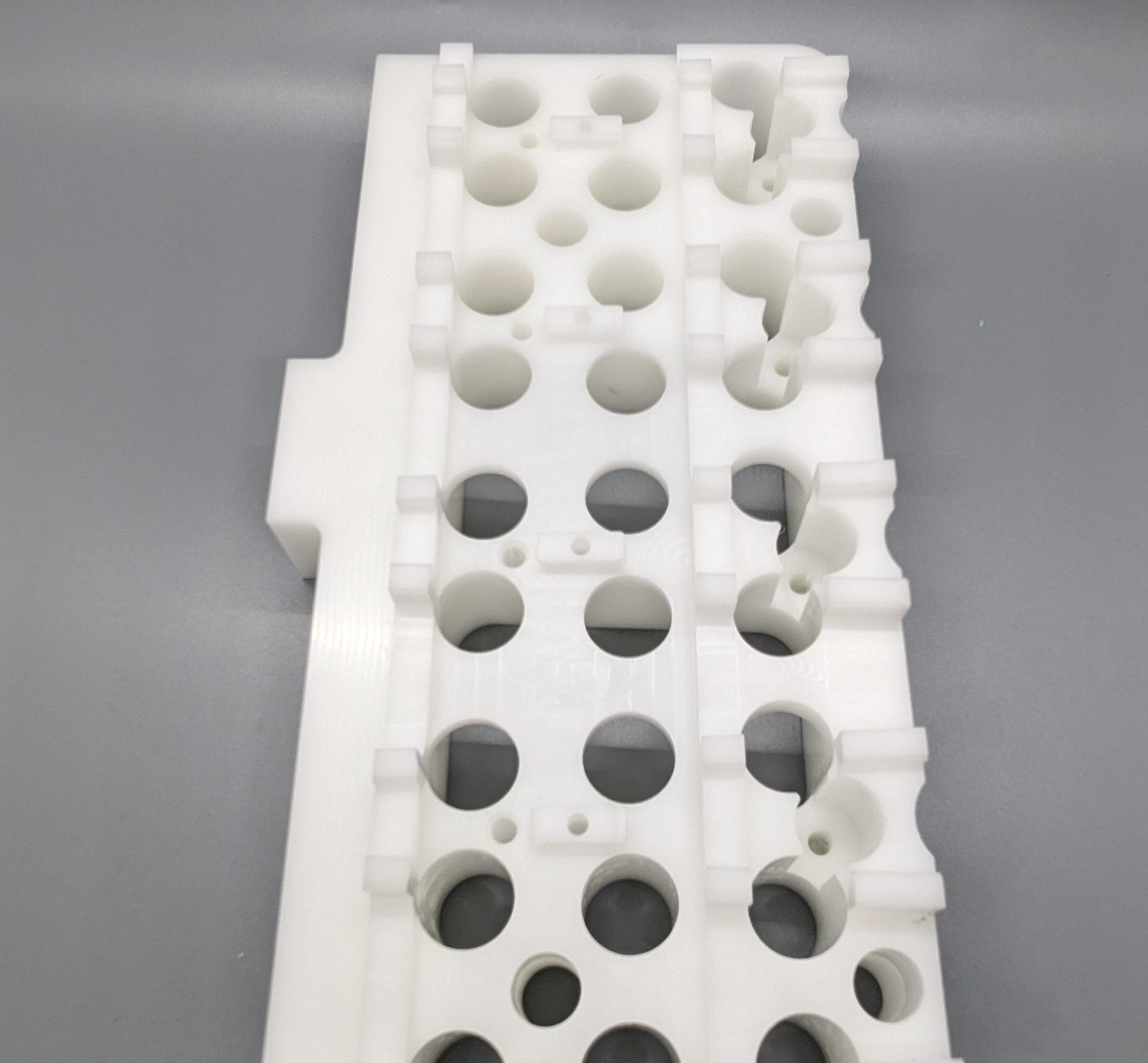

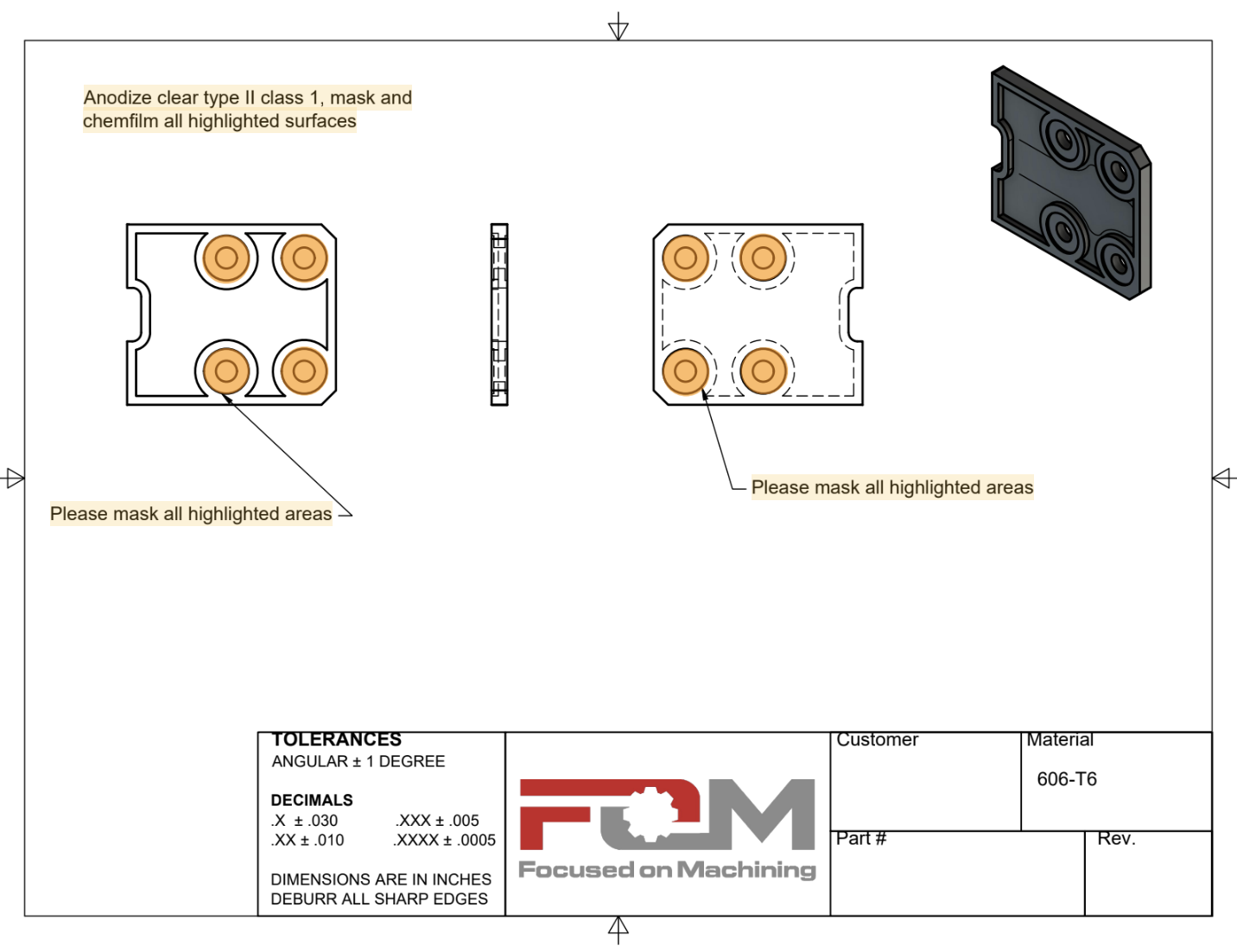

What to Know about Complex Masking Requirements in Precision Machinin

When shops quote customers high costs and long lead times for anodized parts, often it’s because the masking requirements are exceedingly complex. In some cases, complex masking requirements can double the price of a part.

Keep reading for our AS9100 machine shop’s insights into complex masking and tips for getting your parts faster and more cost-effectively.

When shops quote customers high costs and long lead times for anodized parts, often it’s because the masking requirements are exceedingly complex. In some cases, complex masking requirements can double the price of a part.

Keep reading for our AS9100 machine shop’s insights into complex masking and tips for getting your parts faster and more cost-effectively.

Complex Masking = Higher Costs and Longer Lead Times

Masking is an entirely manual process that requires meticulous attention to detail. Flat, smooth surfaces are easy enough to mask. But when it comes to masking only a portion of a surface or small and intricate features, the process can be surprisingly time-consuming.

We once sent a lot of 15 parts to our trusted plating vendor, and it took them all day to mask just three parts. That’s not because the person doing the masking was slow or bad at their job. On the contrary, it’s because they’re great at their job and willing to put in the time and effort required to get it done right.

Since time is money in manufacturing, complex masking can add significantly to the cost per part. In this particular case, the plating vendor charged $300 per piece for the masking alone.

It’s worth noting that complex masking requirements can also cause delays during the quoting phase of a precision machining project. It can take an extra couple of days for a machine shop to receive an accurate estimate from a plating vendor.

Consider Chem Film to Avoid Complex Masking

As an AS9100 machine shop, we receive many anodizing requests from aerospace and space customers. Anodizing seals the surface of an aluminum part, providing a durable, corrosion-resistant coating that can withstand significant wear in extreme environments.

Because an anodized coating is electrically non-conductive, some of our space customers want certain features masked to maintain conductivity. While this request is completely valid, we like to encourage these customers to consider a chem film coating as an alternative to anodizing.

Like anodizing, chem film seals an aluminum surface and protects it from corrosion and wear. However, unlike anodizing, chem film helps conduct electricity. In other words, by selecting chem film over anodizing, space customers enjoy most of the benefits of anodizing without having to worry about costly and time-consuming masking.

Simplify Masking Requirements When Possible

We understand that customers whose parts require superior durability and wear resistance may not have the option of choosing chem film. In these cases, there are steps to take to simplify masking requirements.

When your objective is maintaining electrical conductivity, we recommend plugging threaded holes. It’s possible to achieve electrical conductivity through a threaded hole. And inserting a rubber plug into a hole is easier (i.e., faster and more cost-effective) than masking an intricate feature.

Another best practice is to mask large, smooth, flat surfaces instead of intricate features.

When You Need Complex Masking, Trust Our AS9100 Machine Shop

Can’t avoid complex masking? Don’t worry—Focused on Machining will make it happen. We just like to set clear expectations with customers about how complex masking can affect costs and lead times. It’s always a good idea to plan these projects well in advance.

We have solid partnerships with some of the best plating shops in the country, and these shops specialize in complex masking. Over the years, we’ve refined our method for communicating complex masking requirements to plating partners. Our standard is to create our own masking prints that highlight areas requiring masking to make their jobs as easy as possible.

Request a quote from our AS9100 machine shop today!

A Proven Approach to Quoting Accurate Precision Machining Lead Times

When we quote you a lead time at Focused on Machining, you can be confident that we’ll meet it.

That’s because, unlike many shops that base their quoted lead times on instinct alone, our aerospace machine shop takes a much more strategic approach. Specifically, we leverage our ERP system to build a detailed schedule that accounts for many factors—from material sourcing and outside processing to our shop’s internal capacity.

When we quote you a lead time at Focused on Machining, you can be confident that we’ll meet it.

That’s because, unlike many shops that base their quoted lead times on instinct alone, our aerospace machine shop takes a much more strategic approach. Specifically, we leverage our ERP system to build a detailed schedule that accounts for many factors—from material sourcing and outside processing to our shop’s internal capacity.

The Nuances of Scheduling Precision Machining Jobs

Quoting a lead time requires us to consider the factors in our control (i.e., our precision machining capacity) and those outside our control (i.e., material sourcing and outside processing).

As you can imagine, the factors outside our control can be trickier to account for. The scheduling system we developed helps us with both.

Material sourcing and outside processing

When shops miss their quoted lead times, often it's because they failed to factor in shipping times. To avoid this issue, we enter the standard shipping time for each new vendor we set up in our ERP system.

If we’re sending parts across the state of Colorado for anodizing, the shipping time might be only one day. However, if we have to send parts out of state for a unique process like electropolishing, that’s a minimum of 2-3 days in transit (each way), which tells us we need to account for almost an entire week of shipping time.

The same logic applies when sourcing materials. If a material is in stock and the supplier is near our Denver machine shop, they might be able to get it to us in three days. If we need a material from a supplier in Arizona, we’re likely looking at closer to 5-7 business days.

Internal precision machining capacity

With our ERP system, we can look at work already scheduled on every machine in our shop to quickly answer questions like: What job is currently on X machine? How long will it take? When will X machine be free?

Sometimes, we identify a gap in the schedule. For example, we might see that the part we’re working on will finish next week, and the part scheduled behind it isn’t due for another month.

If a customer needs a quick turnaround on a prototype machining job, we may be able to move it ahead and still get all the scheduled jobs completed on time rather than blindly going in order. We can make these strategic decisions because of our diligence in entering the due date for each order and scheduling each machine individually.

How Our ERP System Calculates Accurate Lead Times

Although there are many factors to consider, calculating lead times is quite simple with our ERP system.

When we get a PO, we plug in the due date (the date the customer needs their parts) and other important details about the project. Because we have already entered the standard shipping times associated with materials and outside processes, the system will automatically subtract those days from the due date.

For example, if the parts need to be plated by a vendor in Kansas with a total shipping time of four days, the system will subtract four days from the due date.

We’ll then factor in how long it will take the vendor to plate the parts and subtract that time until we determine the actual number of days we have to complete our internal precision machining processes and the “must leave by date” (the date by which we need to send the parts to the plating vendor to ensure on-time delivery to our customer).

Accommodating expedited lead times

We also use our ERP system to quote expedited lead times. For instance, if a customer needs their parts in three weeks, and we know there will be one week of outside processing and shipping, we can arrange to pay the vendor an expedite fee to turn the parts around faster to meet the customer’s required due date. Understandably, our expedite prices are higher than our standard prices for this reason.

Mitigating Issues to Ensure On-Time Delivery

We proactively communicate with outside processing vendors to ensure they meet their quoted lead times, which is essential for keeping us on track for on-time delivery. However, material sourcing can be more challenging to manage due to the overall unpredictability of material availability.

A supplier may tell us they can get us a specific material in two days, and we’ll include that in our quote. But if the customer takes a couple of weeks to get us a PO, the material may no longer be in stock, potentially impacting our quoted lead time.

We encourage customers to submit POs soon after receiving a quote to avoid these outcomes. We apply this same sense of urgency when processing POs. When we receive a PO, we aim to have it entered into our system within one business day, which includes ordering the material.

If you’re unhappy with other shops’ lead times and on-time delivery rates, we encourage you to reach out to Focused on Machining. We can deliver most parts in 4-6 weeks, and when we tell you that, you can trust that we’re not pulling those numbers out of thin air.

Request a quote from our aerospace machine shop!

Industry Spotlight: Precision Medical Machining

Much like the aerospace industry, the medical industry has strict standards for precision machined parts. And while the AS9100 certification we possess here at Focused on Machining is specific to the aerospace industry, the processes we developed to maintain our status as an AS9100 machine shop enable us to meet the demands of the medical industry, as well.

Much like the aerospace industry, the medical industry has strict standards for precision machined parts. And while the AS9100 certification we possess here at Focused on Machining is specific to the aerospace industry, the processes we developed to maintain our status as an AS9100 machine shop enable us to meet the demands of the medical industry, as well.

4 Reasons to Trust Focused on Machining for Precision Medical Machining

Whether you’re nearby in Colorado or across the country, here’s why you should consider Focused on Machining for precision medical machining.

1. Material traceability

Material traceability is vital for medical parts inserted in the human body or used during surgery; there must be complete certainty that the materials have the necessary properties.

Focused on Machining guarantees material traceability throughout the entire manufacturing process, working only with carefully selected material vendors who provide accurate information, material specifications, and certifications.

2. Precision machining expertise

Medical parts often have intricate features, angles that are difficult to reach, tight tolerances, and high-precision surface finish requirements. A deep level of precision machining expertise is required to successfully manufacture these parts to specification.

Focused on Machining specializes in machining parts with complex features and has developed a reputation for our close attention to detail and superior quality.

We regularly machine stainless steel and acetal—two common materials used in precision medical machining. We’ve even put in the work to master more challenging materials—like titanium, a popular material for medical implants due to its durability, biocompatibility, and excellent strength-to-weight ratio.

3. Well-vetted electropolishing vendors

Parts used in medical environments must meet extremely high standards for cleanliness, and one way to achieve these standards is with electropolishing. This finishing method uses an electrochemical process to smooth a part’s surface, reducing and removing microscopic cracks and crevices that, if left untouched, could enable bacterial growth.

We machine many medical parts from stainless steel (known for its corrosion-resistant and bacteria-resistant properties), achieving a 32 or 24 Ra surface roughness. We’ll then send those parts to a trusted electropolishing vendor, who takes the roughness down to 10 or 8 Ra, which is essentially a mirror-like finish.

Focused on Machining facilitates coordination with vendors, taking on project management responsibilities to alleviate our customers of this burden.

4. Rigorous inspection process

We worked hard to improve our inspection process as part of our journey to becoming an AS9100 machine shop.

Each part is subject to a First Article Inspection, which means as soon as we finish an operation for the first time, we inspect the part thoroughly to verify that it’s in spec before moving on to the next operation.

If any adjustments are necessary, we cut another part (or re-cut the first part) and then re-inspect it. We document each inspection and maintain that documentation in our ERP system for historical purposes should we need to reference it at a later date.

We proceed through the manufacturing process until the parts are complete and inspect the completed parts per Acceptance Quality Limit (AQL) sampling standards. Upon customer request, we’ll inspect specific features on all parts—simply let us know what you need, and we’ll happily accommodate your preferences.

If parts require a plating process, such as anodizing or passivation, we outsource the service to a certified vendor and obtain the necessary certification(s) from the vendor to include in our quality documentation.

Get Precision Medical Machining Services

One of our primary medical customers builds testing equipment for artificial heart valves, and we make many of the parts for this equipment. We’re excited to take on more precision medical machining projects, especially with the numerous medical companies here in Colorado.

If you’re interested in our services, we’d love to hear from you. Request a quote, and let us put our expertise to work for you.