BLOG

The Importance of Investing in a High-Quality Prototype

We see it all the time: A customer wants an inexpensive prototype delivered as soon as possible, so they order one from an online marketplace. Everything seems okay at first, but eventually, they find out the hard way that when you choose the cheapest option, you get what you paid for.

We see it all the time: A customer wants an inexpensive prototype delivered as soon as possible, so they order one from an online marketplace. Everything seems okay at first, but eventually, they find out the hard way that when you choose the cheapest option, you get what you paid for.

The first sign of problems typically occurs when the customer needs to assemble the prototype into a product, and it doesn’t fit right. Or when they’re ready to start production, and the prototype hasn’t been optimized for fast and cost-effective manufacturing at scale. In some cases, the customer may not notice issues until much further down the line when a product wears out quickly or doesn’t perform as well as it should—all because they chose a cheap prototype over a quality prototype to save a little bit of money up front.

We can tell you from experience that if you plan to bring a prototype to production, your best bet is to work with a contract manufacturing services partner you trust from the beginning. Even if you invest more money initially, you’ll save time and money in the long run. The key is to communicate openly with the shop about your plans for the prototype so they can approach the project holistically and help you achieve your long-term goals.

Prototype-to-Production Case Study

Still not convinced? This real-life example might change your thinking.

Struggling to achieve the right fit during prototyping

A sheet metal shop customer of ours was tasked with creating a camera housing for one of their end customers. The sheet metal shop fabricated most of the parts in-house, with the exception of six tight-tolerance parts that had to be machined.

The end customer outsourced the machined parts to a precision machine shop, but when it came time for the sheet metal shop to add them to the assembly, they didn’t fit. They knew the parts hadn’t been designed or machined properly—possibly both.

The sheet metal shop elected to take matters into its own hands, convincing the end customer to let them choose a vendor for the machined parts and manage the relationship. They reached out to Focused on Machining to create prototypes of the machined parts, which would eventually be produced in higher volumes. But they thought our prototype pricing was too high. So, they turned to a less expensive precision machine shop.

Though the precision machine shop did a fine job on the parts, the sheet metal shop decided they wanted a local contract manufacturing services partner to maintain better control of the process and slash lead times. That’s when they reached back out to Focused on Machining.

This time, the sheet metal shop customer was more open to spending money upfront to save money in the long run. They had proven the concept with the previous shop and knew that if we could achieve the required tolerances, the parts would fit together perfectly. This is where clear communication between the customer and us was crucial.

Communicating openly to align on long-term goals

The sheet metal shop customer wanted a small batch of 25 parts each to start. They shared their target price per part for high-volume production while acknowledging that the price per part would be higher for an order of 25. They asked us to quote the batch of 25 parts however we needed to, but made it clear that they expected us to hit a lower price point eventually.

We happily agreed to these terms.

Quoting the initial 25-part order higher than the customer’s target price per part allowed us to spend time building the proper fixturing, which was essential for achieving the parts’ tight tolerances quickly and accurately.

We then calculated the maximum amount of precision machining time that would allow us to hit our customer’s target price per part and determined how to stay within that parameter. Our next step was investing in high-quality tooling, which was expensive but would enable us to achieve better speed and precision.

Finally, we ran the 25 parts and delivered them to the customer. Their response? “You guys make really beautiful parts!” The machined parts fit into the assembly perfectly with no issues. The end customer was thrilled and put in an order for 100 parts per month, which the sheet metal shop will outsource to Focused on Machining.

Because we were given the flexibility to put in the extra work during prototyping to perfect our process, we can now hit our customer’s target price point for high-volume production without a problem.

The moral of the story is…

…if you’re developing a prototype that you plan to transition to production, tell us your goals from the start. Let us do the prototyping at a cost that makes sense (yes—a higher cost than an online parts marketplace), and we’ll ensure that you’re wildly successful during production. The extra money you invest upfront will pay off in the long run.

A Game-Changing Approach to Achieving CMMC 2.0 Compliance

Any manufacturer pursuing CMMC 2.0 compliance will tell you that the process is rigorous, to say the least. Focused on Machining is currently working to achieve Level 2 certification, which has a long list of 110 requirements aligned to NIST SP 800-171. We anticipate that our journey to CMMC certification will take us a total of 18 months when all is said and done.

Any manufacturer pursuing CMMC 2.0 compliance will tell you that the process is rigorous, to say the least. Focused on Machining is currently working to achieve Level 2 certification, which has a long list of 110 requirements aligned to NIST SP 800-171. We anticipate that our journey to CMMC certification will take us a total of 18 months when all is said and done.

As a quick refresher, the US Department of Defense (DoD) is mandating that all manufacturing suppliers acquire and maintain CMMC certification to prove they meet strict cybersecurity standards.

Understandably, not all shops have the time, money, or resources to complete such a rigorous process. CMMC 2.0 compliance consultants and IT professionals are available for support, but they charge well into the six figures. Rather than paying such a hefty price or attempting the process themselves, many small shops are opting out of CMMC 2.0 compliance entirely.

This means that by the time the requirement takes effect in 2024, the DoD is poised to lose a large number of suppliers. That’s an especially tough pill to swallow at a time when their supplier base is already shrinking for unrelated reasons, such as shop owners reaching retirement age and shutting down or consolidating.

Focused on Machining recognizes the challenges surrounding CMMC certification for DoD customers and suppliers alike. But we knew that opting out of CMMC 2.0 compliance simply wasn’t an option for our aerospace, space, and defense-focused shop. In fact, we wanted to get ahead of the game and become certified before the requirement even takes effect. So, we found a way to be part of the solution.

Using Our ERP System to Manage the CMMC Certification Process

Faced with the prospect of dedicating a year and a half to pursuing CMMC 2.0 compliance, we set out to determine how to manage such a complex process without hiring an expensive consultant or IT professional. From the beginning, our goal was to keep the associated costs as low as possible so we wouldn’t have to pass those costs on to customers through increased prices.

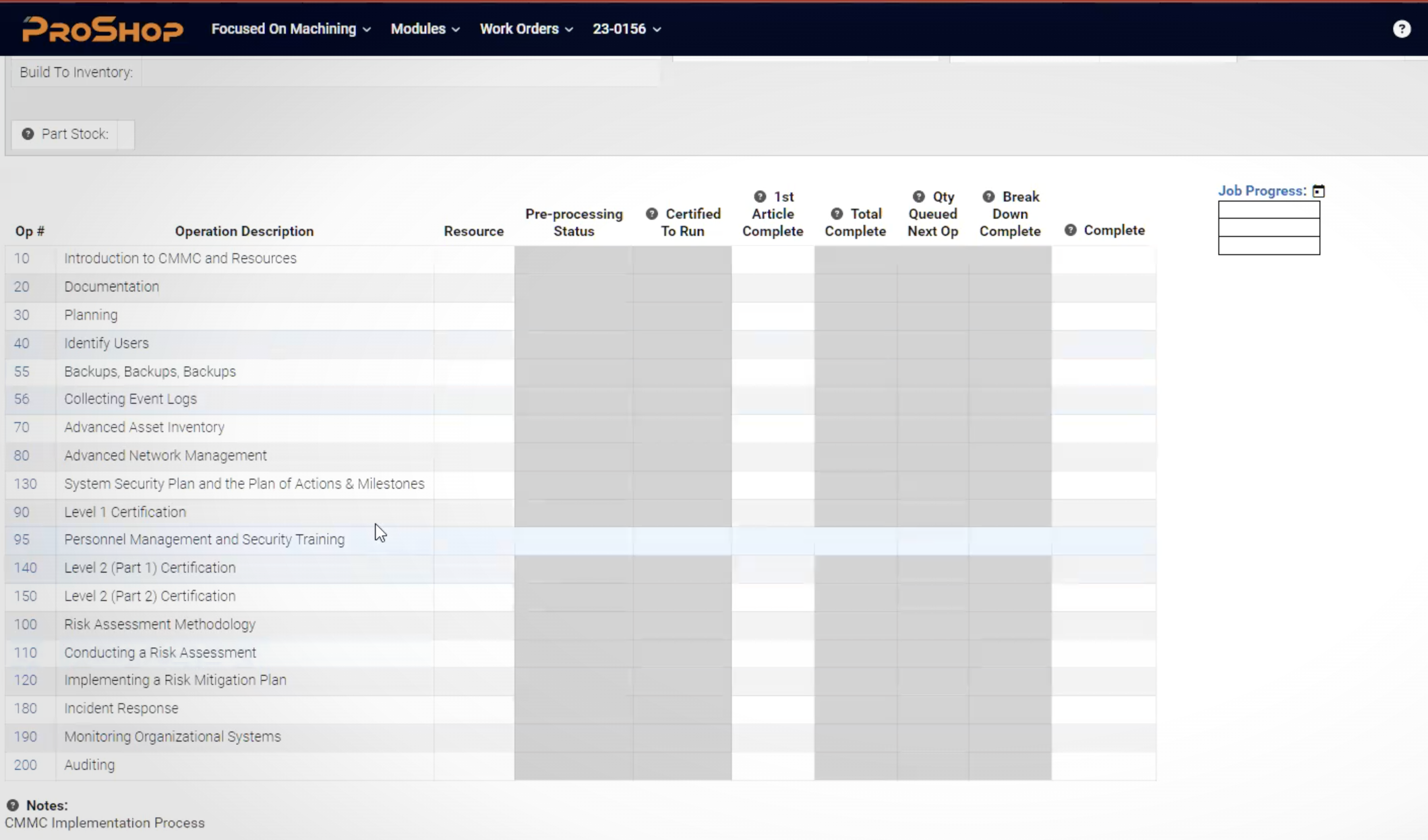

We thought, “Why not approach the process the same way we would a complex part?” Naturally, that idea led us to our ERP system, ProShop.

When making a part for a customer, we create a work order in ProShop outlining a long series of steps to complete the part. All related documentation is stored in the system for easy access. We check off each step as we complete it so everyone can view where we are in the process.

Here’s a look at the work order we created along with the ProShop team for CMMC 2.0 compliance:

When we click on each of these operations, a new page opens where we can view the steps that must be completed and who is responsible. The assigned team member completes the step and marks it as such.

During our eventual CMMC audit, we’ll be able to walk the auditor through the work order and show them proof of specific tasks and documentation. We took a similar approach when we went through the AS9100 certification process, and it was very successful.

A digital solution to benefit manufacturers everywhere

Ultimately, manufacturers everywhere will have the chance to benefit from our CMMC 2.0 compliance work order. Once we complete the process ourselves and optimize the work order to be as useful as possible, ProShop will release it as a module available for purchase.

We hope this offering will enable more shops to opt in to pursue CMMC 2.0 compliance. Because while those shops may be our competitors, we know they are a critical part of the American manufacturing industry that we love so much.

Are you looking for a machining partner ahead of the game in achieving CMMC certification? Request a quote from Focused on Machining!

Improving Precision and Efficiency with Multi-Axis Machining

As an aerospace machining shop committed to innovation and continuous improvement, it was only a matter of time before we progressed from standard CNC milling to multi-axis machining. Keep reading to learn how our multi-axis machining capabilities empower us to deliver unparalleled precision and efficiency, setting us apart from other shops offering contract manufacturing in Colorado.

As an aerospace machining shop committed to innovation and continuous improvement, it was only a matter of time before we progressed from standard CNC milling to multi-axis machining.

Keep reading to learn how our multi-axis machining capabilities empower us to deliver unparalleled precision and efficiency, setting us apart from other shops offering contract manufacturing in Colorado.

The Challenge: Machining Complex Parts with Tight Tolerances

We’ve developed a reputation for taking on challenging projects, so we’ve seen an influx of complex parts with features on all sides and tight tolerances. These two factors ultimately drove our decision to implement multi-axis machining at our aerospace machine shop.

Machining a complex part with features on all sides using a traditional vertical mill requires repositioning the part multiple times. This manual process is not only time-consuming but also increases the risk of error—especially when the part has tight tolerances or standard locational tolerances on different sides that demand perfect alignment.

If the machinist doesn’t locate the part absolutely perfectly from one setup to the next, there’s a good chance the part won’t meet the customer’s specifications.

The Solution: Multi-Axis Machining

Multi-axis machining enables us to reduce operations (i.e., human interference) to ensure accuracy, precision, and speed for the most complex parts. Parts that previously required 4-5 operations on a vertical machine are now achievable in 1-2 operations. Here’s how we do it…

The fourth rotational axis

With a bit of ingenuity, we transformed two of our vertical machines into 4-axis machines. Now, in addition to the standard X-axis (side to side), Y-axis (forward and back), and Z-axis (up and down), the integrated fourth rotary axis allows us to rotate a part to machine it from all sides without removing it from its fixturing.

Zero-point fixturing

A cornerstone of each multi-axis machine is the RockLock base, a permanent fixturing setup we invested in for each machine. The RockLock base allows for “easy movement of vises, fixtures, and tooling from machine to machine with no setup time,” enabling incredible precision. For example, we can machine all a part’s OD features, flip the part, and drill tight-tolerance holes on the end without ever having to adjust the fixturing.

How Customers Benefit from Our Multi-Axis Machining Capabilities

Customers seeking contract manufacturing in Colorado will benefit from our multi-axis machining services in the following ways:

Fast lead times. Due to the efficiency of multi-axis machining, we’ve significantly cut the time it takes for parts to move through our shop. In addition to the machining process itself being faster, parts require fewer quality checks since we’re completing multiple operations in one setup.

Incredible accuracy and precision. Reducing the number of setups minimizes the risk of human error that can occur when repositioning a part. As a result, we can achieve tight tolerances and complex features with unbeatable accuracy and precision.

Capacity for high-volume work. Another significant benefit of our increased efficiency is that we have the capacity to take on high-volume production orders and deliver them on time—no problem.

What’s Next at Our Aerospace Machine Shop?

We currently have two machines equipped for multi-axis machining, with a third hitting the shop floor very soon. In even more exciting news, we’re also preparing to welcome our first 5-axis machine, further enhancing our capabilities.

Implementing multi-axis and 5-axis machining is about more than just upgrading technology to us; it’s a commitment to our customers that we’re steadfast in our mission to deliver the highest-quality parts in the shortest time.

Need contract manufacturing in Colorado? Request a quote today, and let us put our advanced technology to work for your complex parts.

Our Journey to CMMC Certification: How We Protect Your CUI

Effective 2024, companies providing manufacturing services for the US Department of Defense (DoD) will be required to maintain a new certification called CMMC (Cybersecurity Maturity Model Certification), proving they meet rigorous cybersecurity standards.

Effective 2024, companies providing manufacturing services for the US Department of Defense (DoD) will be required to maintain a new certification called CMMC (Cybersecurity Maturity Model Certification), proving they meet rigorous cybersecurity standards.

As one of the country’s top defense and aerospace machine shops, Focused on Machining is working hard to achieve CMMC certification.

Although we already follow well-established procedures to protect customer information, the journey to becoming CMMC certified will ensure all sensitive information that comes through our shop is secure to the highest standards of compliance.

What Is CMMC?

According to the US Department of Defense:

“The Cybersecurity Maturity Model Certification (CMMC) program is aligned to DoD’s information security requirements for Defense Industrial Base (DIB) partners. It is designed to enforce protection of sensitive unclassified information that is shared by the Department with its contractors and subcontractors. The program provides the Department increased assurance that contractors and subcontractors are meeting the cybersecurity requirements that apply to acquisition programs and systems that process controlled unclassified information.”

The DoD introduced the initial vision for the CMMC program in 2020 and has spent the past few years refining it. The latest version, CMMC 2.0, has three compliance levels:

Level 1: 15 requirements

Level 2: 110 requirements aligned to NIST SP 800-171

Level 3: 110 requirements based on NIST SP 800-171 & 800-172

Focused on Machining is working to achieve Level 2 certification, as Level 3 is necessary for only the most sensitive aerospace and defense projects.

How Our Defense and Aerospace Machine Shop Is Preparing for CMMC Certification

While CMMC certification is specific to aerospace and defense manufacturing, customers in all industries will benefit from working with a CMMC-certified shop. Essentially, customers can be fully confident that these shops will keep their data safe and secure.

Obtaining CMMC certification is a long and strenuous process—one that can take up to 18 months. But rest assured, we already have many measures in place to help us meet this requirement. Here are several of them:

1. Secure quoting and order entry

During the quoting stage of a project, we use our ITAR-compliant quoting platform, Paperless Parts, to designate ITAR parts, which ensures a high level of protection for CUI (Controlled Unclassified Information), including prints and models.

ProShop, the ERP system we use for order entry, also has ITAR designations. All Focused on Machining employees are ITAR-compliant and can access the information in the system. However, if ever we were to have an employee who isn’t yet ITAR-compliant, the ERP system would prevent them from accessing ITAR files.

2. Employee training and development

We train employees on all best practices and requirements for protecting sensitive information. Employees who have email addresses are trained on how to recognize and avoid phishing scams. All employees are taught how to identify CUI in a print and model and what measures to take to keep that information secure.

3. Restricted and limited access

Justin Quinn, our president, is the only person in our defense and aerospace machine shop permitted to print a copy of a print. We’re also working toward disabling USB slots on computers to ensure employees can’t download data from their computers. Additional multi-factor authentication practices prevent employees from accessing information remotely.

4. Building security

Physical security is just as critical as digital security. We keep our building highly secure, requiring each visitor to come in through the front office and sign in. During the summer, when we open our garage bay to let the air in, we have a gate we close so someone can’t just walk in unless admitted.

5. Vendor engagement

As a general rule, we send vendors just enough information for them to get the job done right. That means none of our vendors are receiving access to customers’ complete prints or models. It can be a tricky balance getting them the right information without disclosing too much, but we’re willing to put in that extra work for our customers.

Some of our vendors are also working to become CMMC certified, and as we move forward, we’ll prioritize working with these vendors.

What's Ahead for Focused on Machining

We began preparing for CMMC certification in March 2023, and while the process is long and involved, we are dedicated to achieving Level 2 certification and confident that we’ll make it happen.

We’ll continue to provide updates throughout the process so all our customers understand the transformative impact that becoming CMMC certified will have on our operations.

It’s Time to Break the Cycle of Over-Tolerancing Parts

While a tolerance of +/- 0.0005” was once considered tight, we now regularly see prints with microscopic tolerances down to +/- 0.0001”. For visual context, a +/- 0.0003” tolerance is like taking a piece of hair, which is about 0.003”, slicing it into ten pieces, and having one of those pieces represent the permitted variance.

A recent trend in the precision machining industry is that customers’ tolerance requirements are becoming increasingly tighter.

While a tolerance of +/- 0.0005” was once considered tight, we now regularly see prints with microscopic tolerances down to +/- 0.0001”. For visual context, a +/- 0.0003” tolerance is like taking a piece of hair, which is about 0.003”, slicing it into ten pieces, and having one of those pieces represent the permitted variance.

Various factors are fueling this trend, but our goal here isn’t to get lost in speculation or finger-pointing. As a solution-focused aerospace machine shop, we’d rather take this opportunity to educate customers about this issue. Because at the end of the day, good communication between shops and customers is key to success.

The Problem with Inspecting Microscopic Tolerances

Achieving microscopic tolerances isn’t a precision machining challenge so much as it is an inspection challenge.

When it comes to quality control, shops have rules of 4, 7, or 10 dictating that the accuracy level of the inspection equipment should be 4, 7, or 10 times greater than the tolerance. So if there is a tolerance of +/- 0.0004”, and a shop is looking for 10 times greater accuracy during inspection, we’re talking about 0.00004”—or 1.3% the width of a human hair.

Only the most advanced inspection equipment in the world is that accurate. Many shops’ CMMs are only accurate to 0.0007” - 0.002”.

Are you getting the part you think you’re getting?

If a shop is tasked with creating holes with microscopic tolerances, they can buy the right tool, place it in the best tool holder, and create those holes perfectly. But when they go to check the holes, they could check them five times and get five different measurements. It’s impossible for them to say with certainty that the holes meet the customer’s specifications.

Maybe the shop’s inspection equipment can verify tolerances of +/- 0.0004” instead of the customer’s requested +/- 0.0001”. The shop will assume the part is acceptable and send it to the customer, but they can’t be 100% certain. And chances are the customer won’t have the ability to inspect the parts better than a CMM at a machine shop.

This common scenario isn’t doing anyone any good—not shops and not customers. Engineers will continue requesting unrealistic tolerances based on the (incorrect) assumption that the shop is meeting their requirements. Shops will be stuck taking on incredible risk to machine parts with rigid specifications without even being able to confidently verify that they got those parts right during inspection.

At Focused on Machining, we consider ourselves up for most challenges. (Case in point: our aerospace machine shop has mastered some of the most difficult materials.) But we end up no-quoting many parts with microscopic tolerances. Why? Because at the end of the day, we only want to take on projects when we’re 100% confident we can deliver what the customer asked for.

A Smarter Way to Approach Tolerances

Keep in mind that nine times out of ten, tolerancing is what drives up the cost of a part. So before calling out a microscopic tolerance on your print, ask yourself if it’s truly necessary for your part’s functionality.

The industry standard tolerances for specific features defined by the American National Standards Institute and the American Society of Mechanical Engineers are sufficient for many parts. The machinists at our aerospace machine shop follow those standards when consulting with customers about their parts, and we advise customers to follow them from the beginning.

For instance, these resources will have standard tolerances for something like an interference fit. You can feel confident that if you adhere to that standard, your part will function well and your shop will be able to meet your specifications quickly and cost-effectively.

At Focused on Machining, we’re always happy to collaborate with customers about the best approach to tolerances. We aim to set every project up for success, which means never promising something we can’t deliver and working with you to ensure you get what you genuinely need. Request a quote to work with us.

Why Our Machine Shop Always Confirms Receipt of POs

Have you ever placed an order online and checked your email inbox for a confirmation email, only to find nothing there? It’s a stressful experience. Without that confirmation email, you have no way of knowing for certain whether your order actually went through.

Have you ever placed an order online and checked your email inbox for a confirmation email, only to find nothing there?

It’s a stressful experience. Without that confirmation email, you have no way of knowing for certain whether your order actually went through.

This is one of the reasons people like shopping on Amazon: they know they can always expect an immediate confirmation email and regular updates about their order status. There’s no sitting around wondering about what’s happening behind the scenes.

Precision machining customers deserve a similarly transparent and seamless experience. That’s why, at Focused on Machining, we have a clear process for confirming receipt of all POs.

Our Process for Confirming Receipt of Precision Machining POs

When you submit a PO for our precision machining services, here’s what you should expect to happen:

We’ll respond with an initial email confirming that we received your order and are in the process of inputting it into our system.

We’ll respond with a final email confirming that the order is in our ERP system, material is on order, and the project is moving forward.

What should you do if you don’t receive either or both confirmation emails?

While our robust internal processes rarely let us down, any shop will tell you that miscommunications can and do happen, especially regarding PO processing. We set the expectation up front that we always confirm receipt of POs so that if, for any reason, you don’t receive either or both of the emails, you know to check in with us.

Here’s a general rule of thumb to follow: if you don’t receive an email confirming that your order has been placed within 2-3 days, reach out to us!

Best Practices for Submitting a PO to Focused on Machining

When you work with Focused on Machining, you might be in contact with various people in the time leading up to submitting your PO. Maybe you speak with an estimator after you request a quote or interact directly with our president, Justin Quinn. So, you might be wondering who to contact when you’re ready to submit a PO.

Here’s a general rule of thumb to follow: always submit POs to orders@focusedonmachining.com.

The simple reason is that multiple people on our team are checking this inbox throughout the day. Response times are fast, and the risk of your submission falling through the cracks is minimal. In contrast, if you send your PO to Justin, there’s a good chance he’s busy and might not be able to respond immediately.

When in Doubt, Communicate

When in doubt, communicate with us! We highly value communicating with customers and are never bothered when a customer checks in with us at any point in the manufacturing process. You deserve to know what’s going on with your project. Furthermore, we’re committed to being open and transparent about the status of your order—whether the news is good, bad, or somewhere in between.

We aim to establish an open communication policy with each customer from the get-go because good communication early on prevents issues down the line.

Request a quote to discuss your next precision machining project!